GENERAL

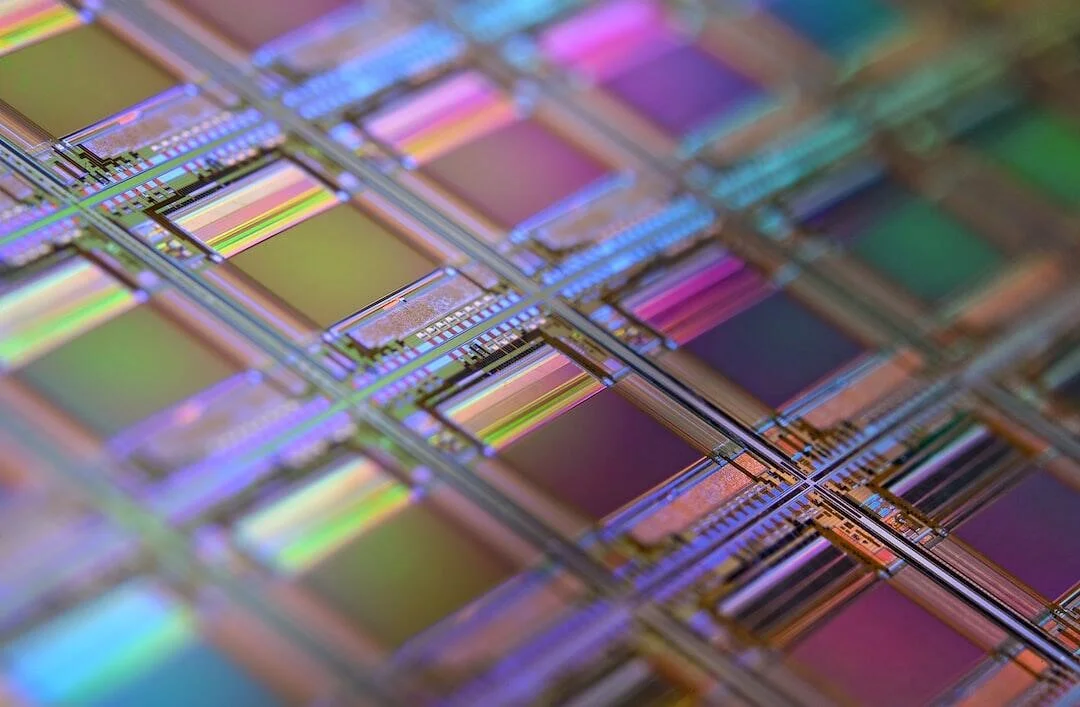

8 Key Factors to Consider When Selecting a Silicon Wafer Supplier

Finding the right silicon wafer suppliers can make or break your project. Whether you’re in the test wafer industry or engaged in cutting-edge research, you need someone you can trust.

With so many options out there, it’s essential to cut through the noise and find a partner that truly understands your needs. In this guide, we’ll uncover the key factors to help you make a confident choice.

Ready to get started? Let’s go!

1. Quality of Silicon Wafers

High-quality wafers ensure the reliable performance and longevity of your products. Look for those with minimal defects and a uniform crystalline structure.

Surface purity is also critical, as impurities can lead to failures in your electronic components. Consistency in wafer thickness and diameter is essential for precise fabrication processes.

Choose wafer services with thorough quality control and rigorous testing for top-notch wafers. With this, you will pave the way for your project’s success.

2. Supplier Reliability

You need a supplier who consistently delivers on time. Delays can disrupt your production schedule and increase costs.

Reliable silicon wafer suppliers have a proven track record of meeting deadlines. They also provide accurate and consistent product descriptions. This ensures you know exactly what you are getting.

Additionally, make sure to look for vendors with strong customer service. They should be responsive and easy to communicate with.

Suppliers should also offer contingency plans for unforeseen circumstances. This ensures your production continues smoothly, no matter what happens.

3. Pricing and Cost-Effectiveness

Compare the cost of wafers from different suppliers to understand the market rate. However, don’t just aim for the lowest price. Assess the overall cost-effectiveness. This includes the quality and longevity of the wafers.

Search for suppliers that offer competitive pricing without compromising on quality. Sometimes, paying a bit more can save money in the long run due to fewer defects and less downtime.

You may also consider bulk purchase discounts or long-term contracts to get better rates. In addition, be sure to evaluate the total cost of:

- ownership

- incorporating shipping fees

- warranties

- additional costs

Cost-effective vendors provide a balance of fair prices and high-quality products. Plus, they offer transparency and flexibility in their pricing structure.

By doing thorough research and considering these factors, you can ensure you get the best value for your investment.

4. Customization Options

Every project has unique requirements, and having a supplier that offers customization is critical. Look for a provider that can tailor the wafer specifications to your needs. This includes:

Custom Sizes

Custom sizes are essential to meet the specific demands of various applications. Suppliers should offer a range of diameters and dimensions to accommodate different fabrication processes.

Custom sizing allows precise engineering and optimized material use. Plus, it improves the overall efficiency and effectiveness of your production workflow.

Thicknesses

Choosing the right thickness is key for the structural integrity and performance of your wafers. Different processes and technologies need varying thickness levels for optimal results.

A dependable supplier should provide multiple thickness options to cater to diverse project needs. Moreover, consistency is key to uniform device fabrication and avoiding production issues.

Crystalline Orientations

Crystalline orientation crucially affects the electrical and mechanical properties of silicon wafers. Different orientations such as:

- 100

- 110

- 111

Selecting the appropriate orientation ensures optimal performance and reliability of the end device. So make sure to look for suppliers that can produce wafers with various crystalline orientations.

Dopant Levels

A reliable supplier should provide various dopant concentrations for your semiconductor needs. This allows for precise control of electrical properties, such as conductivity and resistivity.

Also, purified dopant materials are essential for high-performance semiconductor devices.

Surface Finishes

The surface finish of silicon wafers plays a crucial role in their performance. An ultra-smooth and defect-free exterior can reduce scattering and improve device yields.

So look for suppliers that offer polished, epitaxial, and other advanced surface finishes to meet stringent technological requirements.

5. Technological Capabilities

High-tech equipment ensures better precision and quality in wafer production. Advanced machinery can handle complex requirements and tighter tolerances.

Modern technology enables efficient mass production. It reduces errors and material waste. Automated systems ensure consistency and faster turnaround times.

Moreover, high-level cleanroom environments prevent contamination. This improves wafer purity and performance.

Choose a supplier that invests in technology upgrades. This ensures they can meet your future needs.

6. Lead Time and Delivery Schedules

Lead time is the period from placing an order to receiving it. It’s wise to choose a supplier with short and predictable lead times. This ensures your project stays on schedule.

Also, delivery schedules refer to the specific dates and times your orders will arrive. Variability in lead times and delivery can disrupt production. It may lead to delays and increased costs.

Choose suppliers who commit to your deadlines and communicate any changes promptly. They should also have the capacity to expedite orders when needed.

With dependable delivery schedules, you can keep your projects running smoothly.

7. Customer Service and Support

When issues arise, you need a vendor who responds quickly and effectively. Find those with knowledgeable support teams. They should be able to give clear and helpful answers to your questions.

Effective communication is also crucial. The supplier should provide multiple ways to contact support, such as phone, email, and live chat.

Additionally, some suppliers offer additional support services such as:

- technical assistance

- troubleshooting

- recommending solutions

This can be invaluable if you encounter complexities with your wafers. Lastly, pay attention to feedback and reviews from other customers. Positive reviews often indicate reliable and efficient customer service.

8. Industry Reputation and Reviews

A silicon wafer supplier’s reputation reflects their reliability and quality. An established supplier like Silyb Wafers often has years of proven experience and satisfied customers. To verify this, you need to:

- check online reviews and testimonials

- get recommendations from industry peers

- confirm their track record

You can also join forums and online communities to get honest feedback. Ask for references and contact them to learn about their experiences with the supplier.

So opt for suppliers with an excellent reputation to ensure that you are partnering with a trusted entity. This will ultimately contribute to the success and efficiency of your projects.

Tips for Finding the Best Silicon Wafer Suppliers

Thank you for taking the time to read our guide on selecting the best silicon wafer suppliers. Choosing the right partner is essential for your project’s success. We hope these tips help you make an informed decision.

Ready to find the right supplier? Don’t wait any longer. Start your search today and ensure your project thrives. Happy sourcing!

Did you find this article helpful? Check out the rest of our blog now!

GENERAL

What Is Hochre? A Creative Introduction

Have you ever stumbled upon a concept that seems to resonate deeply with your thoughts and emotions? Welcome to the world of Hochre. This intriguing term captures not just a practice but an approach to life that encourages creativity, mindfulness, and authenticity. Whether you’re looking for inspiration in your daily routine or seeking a more profound connection with yourself and others, understanding Hochre may just be the key. Join us on this enlightening journey as we delve into what Hochre truly means and how it can transform your everyday experiences. Let’s explore!

Defining Hochre

Hochre isn’t merely a concept; it’s a gateway to discovering deeper levels of creativity and personal expression. Rooted in artistic traditions, Hochre encourages individuals to embrace their unique perspectives.

At its core, Hochre emphasizes authenticity. It pushes aside societal norms that often dictate how we should think or create. Instead, it invites you to engage with your inner voice and let it guide your journey.

This practice combines elements of mindfulness with creative exploration. Participants are encouraged to immerse themselves fully in the moment, cultivating awareness while allowing imagination to flow freely.

Hochre can manifest in various forms artistic endeavors, writing, or even everyday activities infused with creativity. The beauty lies in its adaptability; there are no strict rules or boundaries here. Each person’s approach is as individual as they are, making every experience truly one-of-a-kind.

The History and Evolution of Hochre

Hochre has roots that trace back to ancient cultures. Initially, it served as a means of creative expression, intertwining art and spirituality. Over centuries, various societies adopted and adapted its principles, leading to diverse interpretations.

As globalization progressed, Hochre evolved further. What began as localized practices morphed into a universal concept embraced by many. This cross-cultural exchange introduced new techniques and philosophies while retaining the core essence.

The digital age brought about another transformation for Hochre. Online communities emerged, allowing enthusiasts to share ideas and innovations freely. Social media played a significant role in popularizing these concepts worldwide.

Today’s practitioners continue to explore its depths while blending traditional forms with modern influences. This ongoing evolution keeps Hochre vibrant and relevant in our ever-changing world. Each generation adds layers of meaning that enrich this fascinating practice.

What Makes Hochre Different?

Hochre stands apart from traditional practices with its emphasis on creativity and spontaneity. Unlike rigid methodologies, Hochre encourages fluidity in expression. This unique approach fosters an environment where imagination is key.

Another distinguishing factor is the incorporation of community engagement. Participants often collaborate, sharing ideas that enhance individual experiences. This collective energy cultivates a vibrant atmosphere unlike any other practice.

Moreover, Hochre integrates various art forms seamlessly into its framework. From visual arts to performance pieces, it embraces diversity in creative outlets, allowing for a richer exploration of self-expression.

Hochre’s focus on mindfulness sets it apart as well. Practitioners immerse themselves fully in the present moment while creating or connecting with others nurturing both mental clarity and emotional depth during their journey.

How to Incorporate Hochre Into Your Daily Life

Integrating Hochre into your everyday routine can bring profound change. Begin gradually by spending a few minutes daily on mindfulness, such as pausing to take deep breaths and center your mind.

Next, consider integrating creative activities that resonate with you whether it’s sketching, journaling, or playing music. These outlets help cultivate the essence of Hochre while allowing self-expression.

Another way is to connect with nature. Connect with nature by spending time outside, whether taking a stroll in the park or caring for your garden. Nature has an innate ability to ground us and enhance our connection with the world around us.

Engage in community events or workshops focused on creativity and collaboration. Surrounding yourself with like-minded individuals fosters inspiration and motivation as you explore Hochre together. Embrace these moments fully; they enrich both your understanding and practice of this unique concept.

Benefits of Practicing Hochre

Practicing Hochre offers a myriad of benefits that can enrich both your mind and body. One significant advantage is enhanced creativity. Engaging in this unique practice stimulates imaginative thinking, allowing you to explore ideas freely.

Additionally, Hochre fosters mindfulness. By focusing on the present moment, it helps reduce stress and anxiety levels. This sense of calm can lead to improved emotional well-being.

Another benefit lies in community building. Participating in Hochre often involves gathering with like-minded individuals who share similar interests and goals. Such connections can be incredibly rewarding.

Moreover, practicing Hochre encourages discipline and commitment. Regular engagement cultivates consistency, which is vital for personal growth.

Many find that incorporating Hochre into their routine enhances overall life satisfaction through increased joy and fulfillment from daily activities. Each aspect contributes uniquely to enriching one’s lifestyle experience.

Common Misconceptions About Hochre

Many people assume that hochre is just a passing trend. This couldn’t be further from the truth. Its roots run deep in various cultures and traditions, making it a rich practice with profound significance.

Another misconception is that hochre requires extensive training or special skills. In reality, anyone can start exploring this concept at their own pace. There’s no need for perfection; it’s all about personal expression.

Some think hochre has strict rules to follow. However, its beauty lies in flexibility and creativity. It encourages individuals to adapt practices to fit their unique lifestyles.

Some believe that hochre is only for certain groups of people or ages. This isn’t accurate either it’s inclusive and inviting for everyone, regardless of background or experience level. Embracing hochre means opening doors to new opportunities and connections within our communities.

Conclusion

Hochre represents more than just a practice; it’s an invitation to explore creativity and mindfulness in your daily life. By understanding its definition, history, and unique characteristics, you can appreciate how it has evolved over time.

Incorporating hochre into your routine is not only simple but also rewarding. The benefits are plentiful enhancing focus, boosting creativity, and promoting mental well-being. While there may be some misconceptions surrounding this approach, the essence of hochre remains clear: it’s about embracing the moment.

As you embark on your own journey with hochre, remember that every step taken enriches both your mind and spirit. Dive deep into this world of creativity and let it inspire new dimensions in your everyday experiences.

GENERAL

Herbciepscam: How to Identify Fake Investment Schemes

Introduction to Herbcepscam

The world of investment can be both exciting and perilous. With the promise of high returns often comes the lurking threat of scams, particularly ones disguised as legitimate opportunities. One such scheme is known as a “herbciepscam.” This term may not yet ring familiar to many, but it represents a growing concern in today’s financial landscape. As more individuals seek ways to grow their wealth online, they become prime targets for those looking to exploit their aspirations.

Understanding how these scams operate is crucial for anyone interested in investing their hard-earned money. In this blog post, we’ll uncover the ins and outs of herbciepscams. Whether you’re an experienced investor or just starting out, knowing how to recognize these fraudulent schemes will help safeguard your finances and ensure that you make informed decisions in your investment journey. Let’s delve deeper into this critical topic so you can protect yourself from falling prey to deceitful tactics!

How to Spot a Fake Investment Scheme

Spotting a fake investment scheme can be challenging, but certain characteristics often reveal the truth.

First, be skeptical of promises that seem too good to be true. High returns with little risk are red flags. Always ask yourself if it sounds realistic.

Next, check for transparency. Legitimate investments provide clear information about their operations and risks involved. If details are vague or hard to find, proceed with caution.

Look into the people behind the scheme as well. Research their backgrounds and qualifications. A lack of credible experience should raise alarms.

Trust your instincts. If something feels off or pressured decisions arise, take a step back. Genuine opportunities allow you time to think things through without rushing you into commitments.

Remember these tips when evaluating potential investments; staying vigilant is key in navigating this landscape effectively.

Warning Signs of a Herbcepscam

One of the most telling signs of a herbcepscam is the promise of unrealistic returns. If an investment promises returns that seem unrealistically high, it’s likely a scam.

Another red flag is pressure tactics. If someone rushes you into making a decision without giving you time to think or research, take a step back.

Lack of transparency also raises concerns. Be wary if details about the investment are vague or if you’re unable to find clear information about how your money will be used.

Additionally, check for unlicensed operators. Legitimate investments should involve regulated entities and professionals with proper credentials.

Watch out for testimonials that seem overly polished or generic. Authentic feedback usually comes from real experiences and can provide valuable insights into the legitimacy of an opportunity.

Real Life Examples of Herbcepscam

Many individuals have fallen prey to the herbcepscam phenomenon, with stories emerging from various parts of the globe. One notable case involved a woman who invested her life savings into a seemingly promising herbal supplement fund. The scheme promised exorbitant returns that never materialized.

Another example is a group of retirees lured by aggressive online advertising promoting an “exclusive” trading platform for medicinal herbs. After months of initial gains, their accounts disappeared overnight.

Social media has amplified these scams, where fake endorsements often mislead potential investors into believing in fictitious success stories. Victims report feeling embarrassed and isolated after realizing they were conned.

Trusting testimonials or flashy websites can lead to devastating losses. These examples serve as cautionary tales reminding everyone to approach investment opportunities with skepticism and thorough research before committing funds.

Steps to Take if You’ve Fallen Victim to a Herbcepscam

If you believe you’ve fallen victim to a herbciepscam, swift action is crucial. First, gather all documentation related to the investment. This includes emails, transaction records, and any correspondence with the scammers.

Next, contact your bank or credit card company immediately. They may be able to reverse charges or block further transactions.

Report the scam to local authorities and relevant financial regulators. Providing them with detailed information can help prevent others from becoming victims.

Consider seeking legal advice if significant amounts of money are involved. A professional can guide you on the best course of action for recovery.

Share your experience online or within community forums dedicated to fraud awareness. Your story could help others recognize similar scams before it’s too late.

How to Protect Yourself from Falling for a Herbcepscam

Protecting yourself from a Herbcepscam requires vigilance. Always conduct thorough research before investing your money. Look for reviews and feedback from reliable sources.

Stay skeptical of promises that seem too good to be true. Promises of big profits with minimal risk are usually warning signs.

Be wary of unsolicited offers, especially through social media or email. Scammers frequently use these platforms to reach potential victims.

Consider consulting with a financial advisor before making decisions. Their expertise can provide valuable insights and guidance in navigating investment opportunities.

Keep personal information secure and avoid sharing sensitive details without verifying the legitimacy of the entity you’re dealing with.

Educate yourself about common scams by reading articles or joining forums focused on financial safety. Knowledge is one of your strongest defenses against deception in the investment world.

Conclusion

Herbciepscam is a growing concern in today’s investment landscape. As people seek ways to grow their wealth, they often encounter scams that take advantage of their hopes and dreams. Being able to identify these fake schemes is crucial for protecting your finances.

Recognizing the signs of a herbciepscam involves staying vigilant. If an offer sounds too good to be true or promises unrealistic returns, approach it with caution. High-pressure tactics and lack of transparency are also red flags you should never ignore.

Real-life examples show just how damaging these scams can be. Many individuals have lost significant amounts of money by falling prey to deceptive tactics posing as legitimate investments. Understanding these cases can help you stay informed about potential threats.

If you’ve already fallen victim, don’t lose hope. Take immediate action by reporting the scam to authorities and seeking legal advice if necessary. Recovery may not always be possible, but knowing your rights can aid in navigating this difficult situation.

Protecting yourself from becoming part of a herbciepscam requires education and vigilance. Conduct thorough research before investing, verify claims made by promoters, and consult financial advisors when unsure about opportunities presented to you.

Staying informed is key in the fight against investment frauds like herbciepscam. Equip yourself with knowledge and look out for warning signs so that you remain one step ahead in safeguarding your investments.

GENERAL

Pertadad: Ancient Roots and Its Modern Philosophical Impact

Introduction to Pertadad

Imagine a philosophy that intertwines ancient wisdom with modern living. This is the essence of Pertadad, a profound system of thought and practice rooted in centuries-old traditions. As we navigate through the complexities of contemporary life, many are turning to this rich tapestry of teachings for guidance and inspiration.

Pertadad invites us to explore our inner selves while fostering connections with others and the world around us. Its principles resonate deeply in today’s fast-paced society, offering insights into mindfulness, community, and personal growth. Join us on this journey as we delve into the origins, evolution, and relevance of Pertadad today a path many are finding essential for navigating their lives with purpose and clarity.

The origin and meaning of Pertadad

Pertadad has roots steeped in ancient traditions, often linked to wisdom and enlightenment. The term itself is believed to originate from a blend of old languages that convey concepts of balance and harmony.

At its core, Pertadad signifies a quest for understanding one’s place in the universe. It emphasizes the interconnectedness of all beings and highlights the importance of self-awareness.

The philosophies surrounding Pertadad encourage individuals to explore their consciousness. This exploration opens doors to deeper insights about life’s purpose and our relationships with others.

As cultures evolved, so did the interpretations of Pertadad’s meaning. While some may view it as philosophical doctrine, others see it as a spiritual guide leading towards personal growth.

This rich tapestry continues to inspire seekers today, urging them toward self-discovery and unity with nature.

Historical significance of Pertadad in ancient cultures

Pertadad holds a profound place in the tapestry of ancient cultures. This philosophy emerged as a guiding force, shaping societal norms and values across different civilizations.

In many early societies, Pertadad principles influenced governance and community living. Leaders often turned to its teachings for wisdom on maintaining harmony and justice among their people.

Rituals rooted in Pertadad fostered connections between individuals and the divine. These practices created a sense of belonging that transcended time, linking generations through shared beliefs.

Art and literature from these eras reflect Pertadad’s impact as well. Poets celebrated its philosophies, while artists depicted scenes that embodied its core tenets—balance, respect for nature, and inner peace.

As trade routes expanded, so did the reach of Pertadad. Ideas traveled alongside goods, intertwining with local customs to create rich cultural exchanges that still resonate today.

The evolution of Pertadad’s philosophies

The philosophies of Pertadad have undergone a fascinating transformation throughout history. Initially rooted in ancient rituals and communal practices, these ideas emphasized connection to nature and the spiritual world.

As societies evolved, so did the interpretations of Pertadad. Scholars began integrating its teachings with emerging philosophical movements, blending them into broader contexts. This adaptability allowed Pertadad to resonate with diverse cultures while retaining its core values.

In modern times, Pertadad’s philosophies emphasize mindfulness and balance. They encourage individuals to reflect on their place within both the community and the cosmos. The teachings promote personal growth through self-awareness.

Today, many practitioners draw from these evolving principles to navigate contemporary challenges. Whether through meditation or community engagement, they find relevance in age-old wisdom that speaks directly to current life experiences.

How Pertadad is practiced today?

Today, Pertadad is practiced in various forms around the world. Communities that embrace this ancient philosophy often gather for rituals and discussions. These gatherings create a space for sharing experiences and insights.

Many followers integrate Pertadad principles into daily life. They focus on mindfulness, promoting self-awareness through meditation and reflection. This method enables people to tune into their inner being.

Modern interpretations of Pertadad also emphasize sustainability and respect for nature. Practitioners advocate for eco-friendly living, harmonizing their lifestyles with the environment’s needs.

Online platforms have emerged as well, allowing enthusiasts to share knowledge and resources. Webinars, podcasts, and forums offer fresh perspectives while fostering connection among people who value Pertadad teachings.

Workshops are increasingly popular too; they provide hands-on experiences that deepen understanding of these age-old philosophies in contemporary settings.

Key teachings and principles of Pertadad philosophy

The essence of Pertadad philosophy lies in harmony. It highlights the importance of harmony within yourself and with your surroundings. This concept encourages individuals to seek equilibrium between their minds, bodies, and spirits.

Another significant teaching is mindfulness. Practitioners are urged to live in the present moment, fostering awareness of thoughts and emotions without judgment. This practice enhances clarity and emotional resilience.

Community plays a vital role too. Pertadad teaches that interconnectedness among people strengthens relationships and enriches lives. Sharing wisdom fosters collective growth.

Adaptability is key within Pertadad teachings as well. Embracing change allows for personal evolution while navigating life’s challenges smoothly.

Gratitude forms a foundation for happiness in this philosophy. Recognizing daily blessings cultivates a positive mindset that can shift perspectives on even the most difficult circumstances.

The impact of Pertadad on modern society

Pertadad weaves its way through modern society, influencing various aspects of life. Its philosophies encourage individuals to seek harmony within themselves and the world around them. In an age marked by rapid change and stress, these teachings offer a sanctuary.

Many contemporary thinkers draw inspiration from Pertadad’s principles on balance and mindfulness. This ancient wisdom resonates deeply with those seeking purpose in their lives. It encourages self-reflection and personal growth.

Moreover, the rise of wellness movements reflects Pertadad’s emphasis on holistic living. Practices such as meditation, yoga, and sustainable lifestyles echo its core tenets.

Communities are also benefiting from Pertadad’s focus on interconnectedness. Efforts toward environmental conservation often stem from this understanding that all beings share a common existence. The philosophy acts as a guiding light for many striving to make meaningful contributions to society today.

Conclusion: Embracing the wisdom of Pertadad in our lives

Embracing the principles of Pertadad can profoundly enrich our lives. This ancient philosophy offers timeless wisdom that resonates in today’s fast-paced world. By integrating its teachings into our daily routines, we can foster a deeper connection with ourselves and the universe around us.

Practicing mindfulness, valuing community, and nurturing gratitude are just a few ways to incorporate Pertadad’s insights. As we navigate modern complexities, these age-old lessons remind us of what truly matters: balance, harmony, and understanding.

As more individuals explore the depth of Pertadad philosophy, its influence continues to grow. It encourages self-reflection and promotes harmony not only within ourselves but also in our relationships and communities.

The journey into Pertadad is an invitation for personal exploration and growth. Each step taken toward understanding this philosophy cultivates resilience and peace amid life’s challenges. Embracing its wisdom opens doors to a richer experience where tradition meets contemporary life seamlessly.

BUSINESS11 months ago

BUSINESS11 months agoBrand Visibility with Imprint Now and Custom Poly Mailers

HOME IMPROVEMENT11 months ago

HOME IMPROVEMENT11 months agoThe Do’s and Don’ts of Renting Rubbish Bins for Your Next Renovation

BUSINESS12 months ago

BUSINESS12 months agoExploring the Benefits of Commercial Printing

HEALTH7 months ago

HEALTH7 months agoThe Surprising Benefits of Weight Loss Peptides You Need to Know

TECHNOLOGY9 months ago

TECHNOLOGY9 months agoDizipal 608: The Tech Revolution Redefined

HEALTH7 months ago

HEALTH7 months agoYour Guide to Shedding Pounds in the Digital Age

HEALTH10 months ago

HEALTH10 months agoHappy Hippo Kratom Reviews: Read Before You Buy!

HOME IMPROVEMENT7 months ago

HOME IMPROVEMENT7 months agoGet Your Grout to Gleam With These Easy-To-Follow Tips