GENERAL

What Is The Difference Between PCB And PCB Assembly?

Understanding the distinction between printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs) is essential for anyone involved in electronics manufacturing. While both terms sound similar and are often used interchangeably, they refer to different stages in the production process.

A PCB, or printed circuit board, is the foundation for electrical connections and is designed to support and connect various electronic components. On the other hand, PCB assembly services encompass the complete integration of components onto the bare PCB, resulting in a fully functional electronic board ready for operation.

The processes involved in PCB assembly, such as surface-mount technology (SMT) and through-hole insertion, play a crucial role in determining the board’s overall performance and reliability. By understanding these differences, manufacturers can make informed decisions regarding design, assembly techniques, and testing methods, ensuring the quality and functionality of their electronic devices.

PCB assembly services enhance the efficiency of the production process and significantly contribute to the longevity and reliability of the final product. Here is an in-depth look into the difference between PCB and PCB assembly.

Understanding PCB: Definition, Composition, and Functions

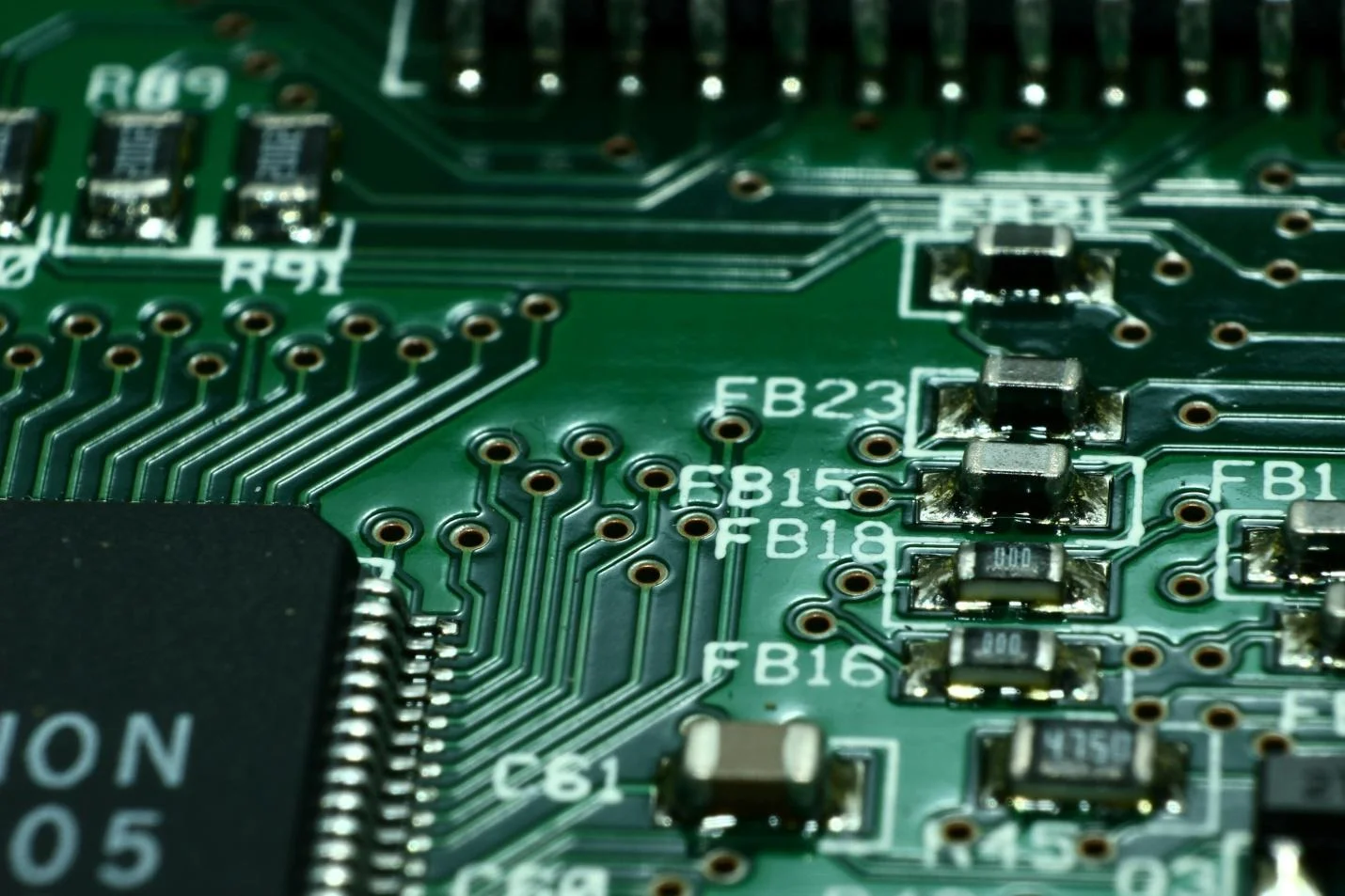

Printed Circuit Boards (PCBs) are essential components in the realm of electronics, serving as the backbone for connecting and supporting electronic components. With their unique design and material composition, PCBs facilitate efficient electrical connections while ensuring reliability and durability. Here, we look into the definition of PCBs, their composition—including the dielectric substrate, copper foil, and solder mask—and their crucial functions in electronic systems.

Definition of PCB (Printed Circuit Board)

A Printed Circuit Board (PCB) is a crucial electronic component foundation for electronic circuits. Often referred to as a printed wiring board, PCBs mechanically support and electrically connect various electronic components through conductive pathways.

These pathways are formed using printed conductive patterns on a dielectric substrate, which helps eliminate manual wiring errors and enables automatic insertion and soldering of components. As a result, PCBs play an essential role in enhancing the quality and reliability of electronic devices.

Composition of PCB

A typical PCB is composed of several key elements that work together to perform its functions:

Dielectric Substrate

The dielectric substrate serves as the base material for the PCB, providing electrical insulation and mechanical support. Common materials used for the substrate include FR-4, a flame-resistant fiberglass-reinforced epoxy, and PTFE for high-frequency applications. The dielectric substrate is critical for ensuring that the electrical pathways do not short-circuit and that the board can withstand various environmental conditions.

Copper Foil

Copper foil is applied to the substrate to create the conductive pathways necessary for electrical connections between components. This copper layer can be etched away to form specific circuit patterns, allowing for precise routing of electrical signals across the PCB. The quality of the copper foil significantly impacts the overall performance and reliability of the PCB, influencing factors like signal integrity and heat dissipation.

Solder Mask

The solder mask is a protective layer covering the copper traces on the PCB, preventing the solder from bridging connections during the assembly process. Typically green in color, the solder mask not only safeguards the copper from oxidation but also ensures that the solder only adheres to designated areas, thus enhancing the reliability of the connections made during PCB assembly.

Functions of PCB

PCBs serve several essential functions that contribute to their critical role in electronic devices:

Electrical Connections

One of the primary functions of a PCB is to provide reliable electrical connections between various components. Manufacturers can use PCB assembly services to ensure that components like resistors, capacitors, and integrated circuits are securely mounted and interconnected. This interconnection is vital for the proper functioning of the electronic device.

Heat Transfer

PCBs also play a crucial role in heat dissipation. The copper traces can act as heat sinks, releasing heat from sensitive components. Effective heat management is essential in high-reliability electronics, and PCB design must account for thermal performance to avoid overheating and potential failure.

Support for Electronic Components

Beyond just electrical connections, PCBs offer mechanical support for electronic components. The design and layout of a PCB allow for the secure mounting of various elements, facilitating both automated assembly processes, such as PCB electronic assembly, and manual insertion where necessary. This structural integrity ensures that components remain in place and function correctly, even under various operational stresses.

Overall, PCBs are fundamental to modern electronic devices, offering the electrical pathways necessary for functionality and the mechanical support and thermal management required for optimal performance. The intricacies of PCB design and assembly highlight the importance of PCB circuit board assembly in producing reliable electronic products.

Moreover, the overall cost of PCBA assembly price is influenced by the quality of materials used and the complexity of the assembly process. With the growing reliance on electronic devices, the demand for efficient and effective PCB assembly services continues to rise.

By understanding the components and functions of PCBs, businesses can make informed decisions about their electronic manufacturing processes and ensure they choose the best options for PCB assembly services that meet their needs.

What is PCBA?

Printed Circuit Board Assembly (PCBA) integrates electronic components onto a printed circuit board (PCB) to create a functional assembly. It involves various methods, including Surface Mounted Technology (SMT) and Dual In-line Package (DIP) techniques, to ensure reliable connections and optimal performance in electronic devices.

PCBA plays a crucial role in the functionality and efficiency of modern electronics, serving as the backbone for countless applications across various industries.

Definition of PCBA (Printed Circuit Board Assembly)

PCBA, or Printed Circuit Board Assembly, integrates electronic components onto a bare PCB. This assembly transforms a bare circuit board into a functional electronic device. The key distinction between a PCB and a PCBA is that a PCB is simply the substrate that holds electronic components. At the same time, a PCBA includes those components, making it a complete assembly for various electronic devices.

Process of PCBA

The PCBA process typically involves two main methods of component integration: Surface Mount Technology (SMT) and Dual In-Line Package (DIP). Each method has unique characteristics that suit different applications.

- Surface Mount Technology (SMT)

SMT is a method where small electronic components are mounted directly onto the surface of the PCB. This process involves several steps:

- Positioning the PCB: The bare PCB is positioned accurately for component placement.

- Printing Solder Paste: Solder paste is applied to the designated areas on the PCB where components will be placed.

- Component Placement: A high-speed pick-and-place machine accurately positions components onto the solder paste.

- Reflow Soldering: The assembly is then passed through a reflow oven, where heat melts the solder paste, creating a permanent bond between the components and the PCB.

SMT is advantageous due to its efficiency and the ability to accommodate high-density component placements, making it suitable for complex electronic devices.

- Dual In-Line Package (DIP)

DIP involves inserting components into drilled holes on the PCB, which is especially useful for larger components incompatible with SMT. The typical steps include:

- Applying Adhesive: A backing glue prevents solder from coating undesired areas.

- Manual or Robotic Insertion: Components are manually inserted or via automated robotic systems.

- Wave Soldering: The PCB is passed over a wave of molten solder that bonds the leads of the inserted components to the PCB.

This method is essential for components that require a more robust mechanical connection or when SMT is not feasible.

Importance of PCBA in Electronic Devices

PCBA plays a crucial role in the functionality and reliability of electronic devices. Here are several key reasons highlighting the importance of PCB assembly services:

- Functional Integration: PCBA ensures that various electronic components, such as resistors, capacitors, and microcontrollers, are appropriately integrated to perform specific functions, enabling the device to operate effectively.

- Quality Assurance: The PCBA process includes rigorous testing and inspection phases to identify and rectify defects, ensuring that the final product meets industry standards for reliability and performance.

- Cost-Effectiveness: Utilizing PCB assembly services helps in reducing overall manufacturing costs. Businesses can lower labor costs by enabling automation and precision in assembly while improving production speed.

- Scalability: As demand for electronic devices increases, PCB assembly services can adapt to produce larger quantities without sacrificing quality, allowing manufacturers to scale production efficiently.

- Versatility in Design: PCBA allows for greater flexibility in circuit design, enabling manufacturers to create more compact and efficient electronic devices. This flexibility is vital for technology innovation.

PCBA is an integral process in producing electronic devices, enabling efficient integration of components and ensuring quality and reliability. The value of PCB assembly services cannot be overstated, as they significantly contribute to the success of electronic products in a competitive market.

The PCBA assembly price often varies based on the complexity of the assembly and the components used, but investing in quality PCB electronic assembly pays dividends in the long run. Moreover, the PCB circuit board assembly process enhances the maintainability and repairability of electronic devices, making it easier to address issues as they arise. Overall, PCBA is a cornerstone of modern electronics, and understanding its components and processes is essential for anyone involved in electronic manufacturing.

Key Differences Between PCB and PCBA

Understanding the differences between Printed Circuit Boards (PCBs) and Printed Circuit Board Assemblies (PCBAs) is essential in the electronics manufacturing industry. While these terms are often used interchangeably, they denote distinct stages in the production process. Below, we outline the key differences based on various aspects.

Composition and Function

PCB: The Bare Board

A PCB is a bare board composed of a dielectric substrate, copper foil, and other materials. It is the foundation for electronic components, enabling electrical connections through its conductive traces. FR4 (flame-resistant fiberglass-reinforced epoxy) and PTFE for high-frequency applications are common materials.

PCBA: The Assembled Board

PCBA, or PCB assembly, refers to a PCB that has undergone assembly processes to incorporate electronic components like resistors, capacitors, and transistors. The assembly process, which includes soldering components onto the board, is critical for providing the necessary connectivity and functionality in electronic devices. The difference between PCB and PCBA highlights the shift from a basic structure to a fully functional electronic circuit.

Process Flow and Machinery

Manufacturing Processes for PCB

Manufacturing PCBs involves several steps, including film generation, etching, drilling, and solder masking. Each step is crucial for ensuring the quality and integrity of the circuit board.

- Film Generation: Creating the PCB image from design files.

- Etching: Removing unwanted copper to form the circuit pattern.

- Drilling: Creating holes for electrical connections between layers.

- Solder Masking: Applying a protective layer prevents the solder from bridging between traces.

Manufacturing Processes for PCBA

In contrast, PCBA involves additional processes beyond those used for PCB manufacturing:

- Solder Printing: Applying solder paste to designated areas.

- Component Placement: Using pick-and-place machines to position electronic components.

- Reflow: Melting the solder to create connections between components and pads.

- Inspection and Testing: Conducting quality checks to ensure proper assembly.

Testing Methods

Testing PCB

Testing for PCBs typically utilizes methods like Fixture Tests and Flying Probe Tests. Fixture Tests involve using a bed-of-nails setup to check the continuity of connections across the board, allowing for simultaneous Testing of multiple points. On the other hand, Flying Probe Tests access points individually and are generally more suited for prototype testing due to their lower cost but slower speed.

Testing PCBA

For PCBAs, the testing methods expand to include In-Circuit Testing (ICT), which checks for manufacturing faults by probing individual components. Functional Testing simulates operating conditions to verify the overall performance of the assembly, making it essential for quality assurance in final products.

Common Defects

Defects Associated with PCB

Common defects encountered in PCBs include:

- Excess or missing copper

- Drilled holes that are incorrect or missing

- Over-etching or under-etching

- Shorts and opens

Defects Associated with PCBA

In PCBAs, potential defects may include:

- Missing components

- Excessive or defective solder joints

- Misalignment of components

These defects necessitate rigorous inspection processes throughout manufacturing to maintain quality standards.

Cost Implications

The cost of PCB assembly services is influenced significantly by the components used and the complexity of the assembly process.

- PCB Costs: Generally lower due to fewer materials and processes involved.

- PCBA Costs: Higher because they encompass the price of electronic components, assembly labor, and additional processes. The PCBA assembly price can vary widely, especially when high-cost components are included.

Production Time

PCB Fabrication Time

Typically, the production time for PCB fabrication ranges from one to three weeks. However, specialized materials or techniques may extend this timeline.

PCBA Assembly Time

In contrast, PCBA production combines the time for both PCB fabrication and the assembly process, which generally results in longer lead times. Sourcing electronic components can take an additional one to four weeks, depending on availability and complexity.

While PCBs and PCBAs play critical roles in electronic devices, they differ significantly in composition, manufacturing processes, testing methods, potential defects, costs, and production timelines. Understanding these differences is vital for optimizing PCB assembly services and ensuring quality in electronic manufacturing.

Applications and Implications of PCB and PCBA

Understanding the differences between printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs) is crucial for various industries that rely on electronic components. This section discusses situations where PCBs are used alone, scenarios that necessitate PCBA, and the broader industry implications of these distinctions.

Situations Where PCBs Are Used Alone

PCBs serve as the foundation for most electronic devices. They are used without components when essential structural integrity or heat dissipation is necessary. Examples include:

- Prototyping: Engineers often utilize bare PCBs to Test and validate circuit designs before committing to a full assembly.

- Non-functional Applications: A PCB might serve a purely mechanical role in specific devices, providing support for other components without needing any electronic functions.

- Simple Circuitry: Bare PCBs can suffice for applications requiring basic connections without complex electronic functions.

Using PCB assembly services in these scenarios is unnecessary, as no components can be mounted. However, when higher performance and functionality are required, the transition to PCBA becomes essential.

Scenarios Necessitating PCBA

While PCBs are essential as stand-alone components, PCBA is critical in applications where electronic functionality is needed. Here are some scenarios that necessitate PCBAs:

- Consumer Electronics: Devices like smartphones, laptops, and tablets require various components integrated onto the PCB to perform their functions. This integration is achieved through PCB assembly services, which combine the PCB with various electronic components such as resistors, capacitors, and microchips.

- Automotive Applications: Modern vehicles rely on complex electronics for safety and performance. PCBAs are integral to anti-lock brakes and navigation systems, where multiple components must communicate efficiently.

- Medical Devices: PCBAs are essential for diagnostic and monitoring devices in the medical field. These applications often require rigorous Testing and high reliability, making PCB assembly crucial to ensure performance under demanding conditions.

- Industrial Equipment: Automation and control systems in manufacturing rely on PCBAs to integrate various sensors and controllers that ensure efficient operation.

In each of these scenarios, the PCB circuit board assembly process becomes vital for ensuring that electronic devices function correctly and reliably.

Industry Implications of Understanding These Differences

Grasping the distinctions between PCBs and PCBAs has far-reaching implications for industries that utilize these technologies. Here are some key considerations:

- Cost Management: Understanding the cost differences between PCB fabrication and PCB assembly is essential for budgeting. The PCB assembly price is typically higher due to the additional components and labor involved. Companies must evaluate the financial implications when choosing between using bare PCBs or opting for complete PCBAs.

- Quality Control: Producing a PCB electronic assembly involves more complexity than a bare PCB. This complexity demands rigorous quality assurance processes to identify defects during manufacturing. Organizations must invest in inspection technologies to ensure that PCBAs meet high standards of reliability and functionality.

- Time to Market: The production time for PCBAs is longer than for bare PCBs due to the assembly process involved. Companies must plan accordingly, mainly when sourcing components, as lead times can vary significantly based on component availability.

- Customization and Design Flexibility: As the demand for customized electronic solutions grows, understanding the differences between PCB and PCBA can lead to better design choices. Companies can leverage PCB assembly services to create tailored solutions that meet specific requirements, enhancing their market competitiveness.

Choosing between PCBs and PCBAs is not merely a technical decision; it has significant implications for cost, quality, production time, and market adaptability. Recognizing when to employ PCB assembly services over bare PCBs is crucial for success in the fast-evolving electronics industry. By understanding these distinctions, companies can optimize their design and production processes, ultimately delivering better products to market.

Incorporating PCB circuit board assembly into strategic planning allows organizations to stay ahead of industry trends while ensuring they effectively meet customer demands.

Final Word

Understanding the distinction between printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs) is crucial for manufacturers and designers alike. This differentiation allows professionals to streamline their design processes and optimize production efficiency.

Knowing the specifics of PCB assembly services ensures that components are integrated correctly and that the final product meets performance standards. As the demand for complex electronic devices grows, so does the importance of quality PCB assembly services in achieving reliable functionality and durability.

The relevance of PCBs and PCBAs in modern electronics cannot be overstated. They serve as the backbone of virtually all electronic devices, pivotal in connecting various components. As technology advances, the complexity of designs increases, making expert PCB assembly services essential for delivering high-quality products.

By prioritizing a clear understanding of PCBs and PCBAs, manufacturers can enhance their designs, improve production timelines, and ultimately deliver superior electronic solutions to their clients.

GENERAL

Novcizpimkunot: Streamlining Workflows for Smarter Decisions

Introduction to Novcizpimkunot

In today’s rapidly evolving business landscape, efficiency reigns supreme. Companies are constantly searching for ways to enhance productivity and make smarter decisions. Enter novcizpimkunot a game changer in workflow management that’s designed to streamline processes and boost decision-making capabilities. This innovative approach takes the chaos out of daily operations, allowing teams to focus on what truly matters: growth and success. Whether you’re a small startup or a large corporation, understanding how novcizpimkunot can transform your workflows is crucial in today’s competitive landscape. Let’s dive into the incredible benefits it offers and explore how it can help elevate your organization to new heights.

The Benefits of Streamlining Workflows

Streamlining workflows brings clarity to complex processes. It simplifies tasks, making them easier to manage. When team members understand their roles and responsibilities, productivity naturally increases.

Eliminating bottlenecks is another advantage. By identifying inefficiencies, businesses can optimize their operations. This leads to faster project completion and improved customer satisfaction.

Cost savings follow closely behind. Reducing wasted time and resources directly impacts the bottom line. Businesses can channel those savings back into expansion and development efforts.

Enhanced communication is also a key benefit of streamlined workflows. Teams that collaborate effectively make informed decisions more swiftly. Information flows seamlessly, ensuring everyone stays on the same page.

Embracing streamlined systems fosters adaptability in a rapidly changing market environment. Organizations become more agile and responsive to new challenges or opportunities as they arise.

How Novcizpimkunot Can Help Improve Decision Making?

Novcizpimkunot revolutionizes the way businesses approach decision-making. By providing a streamlined workflow, it allows teams to access critical data quickly. This efficiency reduces delays and fosters timely decisions.

Its user-friendly interface allows users to effortlessly interpret complex data. Clear insights emerge from data that may have previously seemed overwhelming.

The platform also encourages collaboration among team members. Multiple stakeholders can contribute their perspectives, enhancing the overall quality of decisions made.

Moreover, Novcizpimkunot incorporates analytical tools that predict outcomes based on various scenarios. This feature empowers leaders to make informed choices rather than relying on instinct alone.

By integrating feedback loops within workflows, organizations can adapt strategies swiftly as new information arises. Embracing this adaptability ensures companies stay competitive in fast-paced markets.

Case Studies: Success Stories of Companies Using Novcizpimkunot

Several companies have transformed their operations by adopting novcizpimkunot. One notable example is a mid-sized manufacturing firm that faced persistent delays in project completion. By streamlining their workflows with novcizpimkunot, they reduced lead times by 30%. This dramatic improvement enabled them to meet customer demands more efficiently.

Another case involves a tech startup struggling with communication gaps among team members. After implementing novcizpimkunot, they saw enhanced collaboration and quicker decision-making processes. The result? A boost in product development speed and overall employee morale.

A healthcare provider also leveraged the power of novcizpimkunot to optimize patient scheduling systems. They experienced a significant decrease in appointment cancellations and increased patient satisfaction ratings as a direct outcome of improved workflow management.

These examples highlight the versatility of novcizpimkunot across various industries, showcasing its potential to facilitate smarter business decisions through streamlined operations.

Steps to Implementing Novcizpimkunot in Your Business

Implementing novcizpimkunot in your business begins with a clear understanding of your current workflows. Identify key areas that require improvement and gather input from team members for insights.

Next, choose the right tools or software that align with the novcizpimkunot methodology. These resources will help facilitate smoother transitions and enhance communication.

Training is crucial. Ensure all employees understand how to use new systems effectively. Consider workshops or hands-on sessions to build confidence.

After implementation, monitor progress closely. Use metrics to evaluate efficiency gains and make adjustments as needed.

Encourage open feedback from your team throughout this process. Their experiences can uncover unforeseen challenges and opportunities for further optimization.

Common Challenges and Solutions for Implementing Workflow Streamlining Systems

Implementing workflow streamlining systems like novcizpimkunot can present several challenges. Resistance to change is often at the forefront. Employees may be accustomed to their established routines, making it tough to embrace new processes.

Another common hurdle is inadequate training. Without proper guidance, teams might struggle with adopting the system effectively. Investing in comprehensive training sessions can significantly ease this transition.

Integration issues frequently arise when existing tools are not compatible with new software. Conducting thorough compatibility checks beforehand mitigates this risk.

Data overload can overwhelm users if information isn’t organized clearly within the system. Establishing clear guidelines for data entry and management ensures a smoother experience and enhances decision-making efficiency as intended by novcizpimkunot.

Conclusion

Streamlining workflows has become essential for businesses aiming to enhance efficiency and make smarter decisions. Novcizpimkunot stands out as a powerful tool that empowers organizations to refine their processes, leading to significant improvements in decision-making.

By adopting Novcizpimkunot, companies can experience streamlined operations, reduced redundancy, and enhanced collaboration among teams. The case studies highlight real-world success stories where organizations have seen measurable results after implementing this system.

However, understanding potential challenges during implementation is crucial for a smooth transition. By addressing these obstacles with proactive strategies, businesses can fully leverage the benefits of workflow streamlining.

Embracing novcizpimkunot could be the key to unlocking new levels of productivity and insight within your organization. Take the leap towards smarter decisions today!

GENERAL

Wapbald: The New Digital Language Powering Innovation

Introduction to Wapbald and its origins

In a world where digital communication evolves at lightning speed, a new player has emerged on the scene: Wapbald. This innovative language isn’t just another tool; it’s transforming how we connect and share ideas in our increasingly digital lives. Born from the necessity for efficiency and clarity, Wapbald is carving out its niche as the go-to language for tech-savvy individuals and businesses alike. But what exactly sets it apart? Join us as we explore the origins of Wapbald, its unique features, and how it’s paving the way for revolutionary changes across various industries. Whether you’re a curious learner or a seasoned professional looking to stay ahead of the curve, understanding Wapbald could open doors you never knew existed.

How Wapbald is revolutionizing communication in the digital age?

Wapbald is transforming how we communicate in our fast-paced digital world. This innovative language bridges gaps that traditional languages often overlook.

By using concise syntax and dynamic symbols, Wapbald enhances clarity and reduces misunderstandings. It’s particularly effective in environments where quick exchanges are crucial, such as tech development or customer service.

Visual elements play a significant role too—integrating emojis and icons allows users to convey emotions effortlessly. This multimedia approach resonates especially with younger generations who thrive on visual communication.

Moreover, Wapbald’s adaptability across platforms makes it ideal for social media interactions, video games, and collaborative projects. As businesses increasingly rely on global teams, having a universal language like Wapbald fosters inclusivity among diverse cultures.

This revolution isn’t just about speed; it’s about enhancing connection in an era dominated by technology-driven interactions.

The unique features of Wapbald and how it differs from other digital languages

Wapbald stands out among digital languages with its innovative syntax and structure. Unlike traditional programming languages, it emphasizes brevity and clarity, allowing users to convey complex ideas in fewer lines of code.

One unique feature is its intuitive visual interface. This makes coding more accessible for beginners while still offering depth for seasoned developers. The drag-and-drop functionality simplifies the learning curve significantly.

Additionally, Wapbald incorporates natural language processing capabilities. Users can write commands that resemble conversational phrases, making it easier to understand and implement instructions without extensive technical jargon.

Another notable aspect is its adaptability across various platforms. Whether it’s web development or mobile applications, Wapbald’s versatility allows seamless integration into different environments.

These attributes position Wapbald as a revolutionary tool in digital communication that fosters collaboration and innovation like never before.

Real-life applications of Wapbald in various industries

Wapbald is making waves across multiple industries, transforming the way we interact with technology and each other. In healthcare, its concise syntax allows for quick communication between doctors and patients, streamlining processes that can often be bogged down by jargon.

In the tech sector, Wapbald simplifies coding languages. Developers find it easier to collaborate on projects using its intuitive structure. This not only boosts productivity but also encourages creativity in problem-solving.

Education is another field where Wapbald shines. Teachers are integrating it into their curricula to prepare students for a digital future. Its engaging format makes learning fun and accessible.

Even marketing teams benefit from this new language. Crafting compelling messages becomes more effective when using Wapbald’s unique features tailored for engagement and clarity. The adaptability of Wapbald ensures it meets diverse needs across various sectors seamlessly.

The benefits of learning Wapbald and its potential for career advancement

Learning Wapbald opens up a multitude of career opportunities in today’s tech-driven world. This digital language is becoming increasingly vital in various sectors, from marketing to software development.

Professionals who grasp Wapbald can enhance their communication skills, making collaboration smoother and more efficient. Being fluent in this innovative language sets individuals apart in job interviews and promotions.

Additionally, companies are actively seeking talent proficient in Wapbald for roles that require modern problem-solving techniques. As businesses embrace technological advancements, understanding this digital dialect positions you as an asset.

Moreover, learning Wapbald encourages creativity and adaptability. These qualities are essential for thriving in any industry where innovation is key.

By mastering Wapbald, you’re not just acquiring a new skill; you’re paving the way to exciting prospects that could shape your professional journey significantly.

How to get started with learning Wapbald?

Getting started with Wapbald is easier than you might think. First, immerse yourself in the basics by exploring online resources. Websites dedicated to digital languages often feature introductory guides specific to Wapbald.

Next, consider joining community forums or social media groups focused on Wapbald. Engaging with others can provide real-time support and insights from experienced users.

Practice regularly using interactive tools and applications designed for learning Wapbald. These platforms often include exercises that reinforce your understanding of syntax and semantics.

Additionally, look for webinars or workshops hosted by experts in the field. Live instruction can give you a deeper appreciation of its nuances.

Don’t forget about collaboration! Partnering with fellow learners can enhance your skills through shared knowledge and peer feedback. Embrace this innovative language journey as an exciting opportunity for growth!

Future developments and possibilities for Wapbald

Wapbald is just starting to scratch the surface of its potential. As more people adopt this innovative digital language, we can expect exciting advancements on the horizon.

One possibility lies in integration with AI technologies. Imagine a future where Wapbald algorithms enhance natural language processing, making communication even smoother and more intuitive.

The expansion into educational platforms is another avenue worth exploring. Learning Wapbald could become essential in tech curricula around the world, preparing students for careers in emerging fields.

As industries evolve, so will Wapbald’s applications. From real-time translation services to interactive virtual environments, its versatility may soon be unmatched.

Furthermore, community-driven content creation can fuel rapid growth and adaptability of this language. Users collaborating globally might lead to new dialects or variations that cater to specific needs or cultures.

With innovation at its core, Wapbald’s promises an exhilarating journey ahead.

Conclusion

Wapbald’s represents a significant leap in the way we communicate and innovate in our digital world. Its unique structure and dynamic features set it apart from existing languages, making it an essential tool for various industries. The real-life applications of Wapbald’s are expanding rapidly, showcasing its versatility and potential to streamline processes.

As more professionals recognize the benefits of learning Wapbald’s, career advancement opportunities will likely increase. By embracing this new language, individuals can position themselves at the forefront of technological innovation.

Getting started with Wapbald’s is easier than ever thanks to numerous online resources and communities dedicated to its growth. As interest continues to surge, future developments hold promise for further integrating Wapbald’s into everyday communication.

The journey with Wapbald’s is just beginning. Engaging with this digital language could open doors you never knew existed while shaping how we interact in our increasingly connected world.

GENERAL

What Is Hochre? A Creative Introduction

Have you ever stumbled upon a concept that seems to resonate deeply with your thoughts and emotions? Welcome to the world of Hochre. This intriguing term captures not just a practice but an approach to life that encourages creativity, mindfulness, and authenticity. Whether you’re looking for inspiration in your daily routine or seeking a more profound connection with yourself and others, understanding Hochre may just be the key. Join us on this enlightening journey as we delve into what Hochre truly means and how it can transform your everyday experiences. Let’s explore!

Defining Hochre

Hochre isn’t merely a concept; it’s a gateway to discovering deeper levels of creativity and personal expression. Rooted in artistic traditions, Hochre encourages individuals to embrace their unique perspectives.

At its core, Hochre emphasizes authenticity. It pushes aside societal norms that often dictate how we should think or create. Instead, it invites you to engage with your inner voice and let it guide your journey.

This practice combines elements of mindfulness with creative exploration. Participants are encouraged to immerse themselves fully in the moment, cultivating awareness while allowing imagination to flow freely.

Hochre can manifest in various forms artistic endeavors, writing, or even everyday activities infused with creativity. The beauty lies in its adaptability; there are no strict rules or boundaries here. Each person’s approach is as individual as they are, making every experience truly one-of-a-kind.

The History and Evolution of Hochre

Hochre has roots that trace back to ancient cultures. Initially, it served as a means of creative expression, intertwining art and spirituality. Over centuries, various societies adopted and adapted its principles, leading to diverse interpretations.

As globalization progressed, Hochre evolved further. What began as localized practices morphed into a universal concept embraced by many. This cross-cultural exchange introduced new techniques and philosophies while retaining the core essence.

The digital age brought about another transformation for Hochre. Online communities emerged, allowing enthusiasts to share ideas and innovations freely. Social media played a significant role in popularizing these concepts worldwide.

Today’s practitioners continue to explore its depths while blending traditional forms with modern influences. This ongoing evolution keeps Hochre vibrant and relevant in our ever-changing world. Each generation adds layers of meaning that enrich this fascinating practice.

What Makes Hochre Different?

Hochre stands apart from traditional practices with its emphasis on creativity and spontaneity. Unlike rigid methodologies, Hochre encourages fluidity in expression. This unique approach fosters an environment where imagination is key.

Another distinguishing factor is the incorporation of community engagement. Participants often collaborate, sharing ideas that enhance individual experiences. This collective energy cultivates a vibrant atmosphere unlike any other practice.

Moreover, Hochre integrates various art forms seamlessly into its framework. From visual arts to performance pieces, it embraces diversity in creative outlets, allowing for a richer exploration of self-expression.

Hochre’s focus on mindfulness sets it apart as well. Practitioners immerse themselves fully in the present moment while creating or connecting with others nurturing both mental clarity and emotional depth during their journey.

How to Incorporate Hochre Into Your Daily Life

Integrating Hochre into your everyday routine can bring profound change. Begin gradually by spending a few minutes daily on mindfulness, such as pausing to take deep breaths and center your mind.

Next, consider integrating creative activities that resonate with you whether it’s sketching, journaling, or playing music. These outlets help cultivate the essence of Hochre while allowing self-expression.

Another way is to connect with nature. Connect with nature by spending time outside, whether taking a stroll in the park or caring for your garden. Nature has an innate ability to ground us and enhance our connection with the world around us.

Engage in community events or workshops focused on creativity and collaboration. Surrounding yourself with like-minded individuals fosters inspiration and motivation as you explore Hochre together. Embrace these moments fully; they enrich both your understanding and practice of this unique concept.

Benefits of Practicing Hochre

Practicing Hochre offers a myriad of benefits that can enrich both your mind and body. One significant advantage is enhanced creativity. Engaging in this unique practice stimulates imaginative thinking, allowing you to explore ideas freely.

Additionally, Hochre fosters mindfulness. By focusing on the present moment, it helps reduce stress and anxiety levels. This sense of calm can lead to improved emotional well-being.

Another benefit lies in community building. Participating in Hochre often involves gathering with like-minded individuals who share similar interests and goals. Such connections can be incredibly rewarding.

Moreover, practicing Hochre encourages discipline and commitment. Regular engagement cultivates consistency, which is vital for personal growth.

Many find that incorporating Hochre into their routine enhances overall life satisfaction through increased joy and fulfillment from daily activities. Each aspect contributes uniquely to enriching one’s lifestyle experience.

Common Misconceptions About Hochre

Many people assume that hochre is just a passing trend. This couldn’t be further from the truth. Its roots run deep in various cultures and traditions, making it a rich practice with profound significance.

Another misconception is that hochre requires extensive training or special skills. In reality, anyone can start exploring this concept at their own pace. There’s no need for perfection; it’s all about personal expression.

Some think hochre has strict rules to follow. However, its beauty lies in flexibility and creativity. It encourages individuals to adapt practices to fit their unique lifestyles.

Some believe that hochre is only for certain groups of people or ages. This isn’t accurate either it’s inclusive and inviting for everyone, regardless of background or experience level. Embracing hochre means opening doors to new opportunities and connections within our communities.

Conclusion

Hochre represents more than just a practice; it’s an invitation to explore creativity and mindfulness in your daily life. By understanding its definition, history, and unique characteristics, you can appreciate how it has evolved over time.

Incorporating hochre into your routine is not only simple but also rewarding. The benefits are plentiful enhancing focus, boosting creativity, and promoting mental well-being. While there may be some misconceptions surrounding this approach, the essence of hochre remains clear: it’s about embracing the moment.

As you embark on your own journey with hochre, remember that every step taken enriches both your mind and spirit. Dive deep into this world of creativity and let it inspire new dimensions in your everyday experiences.

HOME IMPROVEMENT11 months ago

HOME IMPROVEMENT11 months agoThe Do’s and Don’ts of Renting Rubbish Bins for Your Next Renovation

BUSINESS12 months ago

BUSINESS12 months agoExploring the Benefits of Commercial Printing

BUSINESS11 months ago

BUSINESS11 months agoBrand Visibility with Imprint Now and Custom Poly Mailers

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoDizipal 608: The Tech Revolution Redefined

HEALTH7 months ago

HEALTH7 months agoThe Surprising Benefits of Weight Loss Peptides You Need to Know

HEALTH7 months ago

HEALTH7 months agoYour Guide to Shedding Pounds in the Digital Age

HEALTH10 months ago

HEALTH10 months agoHappy Hippo Kratom Reviews: Read Before You Buy!

HOME IMPROVEMENT7 months ago

HOME IMPROVEMENT7 months agoGet Your Grout to Gleam With These Easy-To-Follow Tips