BUSINESS

4 Cost-Effective Strategies for Low Volume Manufacturing Success

Are you a small business owner or entrepreneur trying to launch your product without spending too much? You don’t have to rely on high-volume production to succeed.

Low-volume manufacturing can be both cost-effective and efficient. With the right strategies, you can make it work for your business. We’ve put together a list of proven tips to help you succeed in low volume manufacturing.

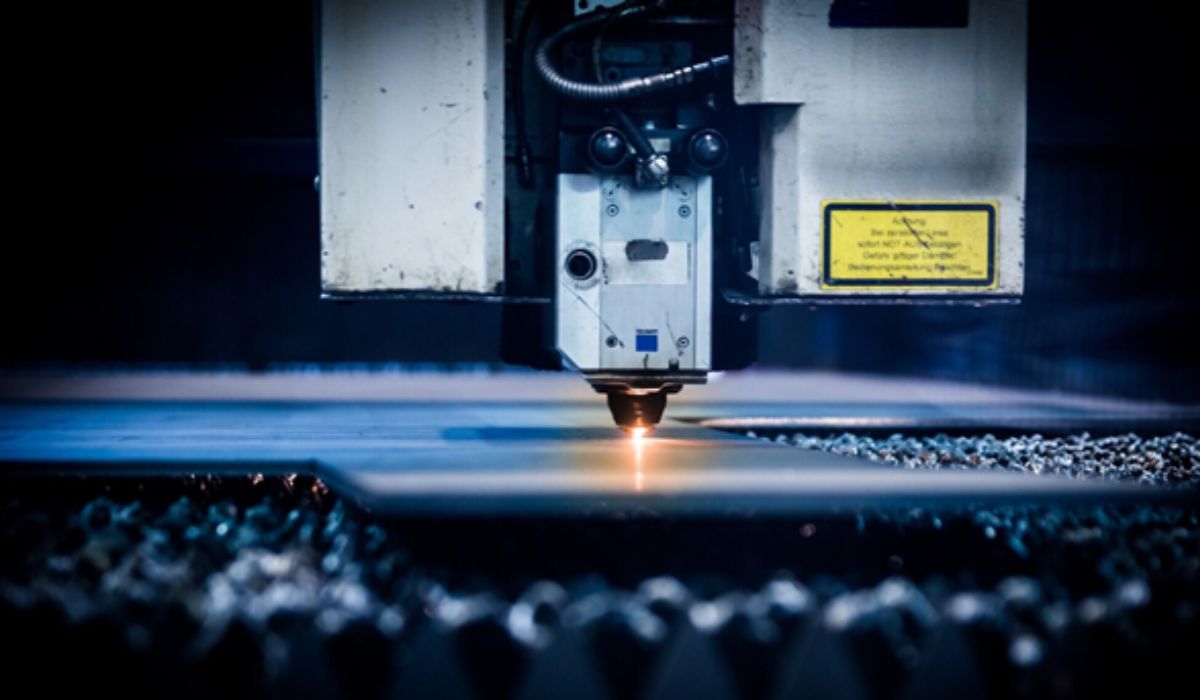

From improving processes to making the most of your materials, we’ll show you how to thrive in laser cut aluminum industry. Get ready to discover valuable insights that will boost your business.

1. Efficient Inventory Management

This means keeping a close eye on your raw materials, work-in-progress, and finished products to cut waste and lower costs. By checking how much you need and have on hand, you can avoid the following:

- buying too much

- or running out of stock

This helps reduce storage costs and keeps production running smoothly without delays. Good inventory management also means the following:

- better use of resources

- higher productivity

- and more profit for businesses

2. Outsourcing Non-core Activities

By delegating tasks such as HR, IT, or logistics to an outside company, manufacturers can focus on their core business activities and improve efficiency. Outsourcing allows businesses to access specialized skills and resources without the burden of the following:

- hiring

- and training extra staff

This not only reduces operational costs but also allows for faster production and delivery times. It also allows companies to adapt to market demands and scale production without the risk of costly investments. By outsourcing non-core activities, low-volume manufacturers can do the following:

- improve their performance

- and compete with larger corporations in the market

This strategy leads to increased profitability and longevity in the competitive manufacturing industry.

3. Lean Manufacturing

This strategy aims to cut waste and boost efficiency in production. By removing unnecessary steps, lowering material and labor costs, and streamlining workflows, businesses can do the following:

- reduce production costs

- and increase profits

Lean manufacturing focuses on continuous improvement, finding ways to make processes more efficient, and helping with the following:

- enhancing product quality

- and delivery times

This approach not only cuts costs but also improves customer satisfaction. Embracing lean principles helps businesses excel in the following:

- low-volume manufacturing

- and stay competitive in the market

4. Utilizing Technology

One of the most effective ways to do so is by utilizing technology, specifically for processes such as laser cutting copper. This technology allows for fast and precise production, resulting in the following:

- reduced labor

- and material costs

Additionally, with the integration of CAD/CAM software, the design and production process becomes more efficient and accurate. By embracing technology, companies can also improve their turnaround time, resulting in the following:

- satisfied customers

- and potential business growth

Navigating the use of laser cutting for copper with technology is a smart and sustainable option for low-volume manufacturing success.

Learn How to Succeed in Low Volume Manufacturing

Implementing cost-effective strategies in low volume manufacturing can significantly contribute to the overall success and profitability of a business. By prioritizing efficiency and minimizing waste, companies can reduce expenses and maximize their resources.

To ensure continued success, it is important to regularly evaluate and adjust these strategies as needed. Start implementing metal cutting laser strategies today and see the positive impact on your bottom line.

Looking for more tips and advice? You’re in the right place! Make sure to bookmark our page and come back to check out more interesting articles.

BUSINESS

cjmonsoon: The Rhythm of Sustainable Growth

Introduction to cjmonsoon and its mission

In a world bustling with change and challenges, finding a business that truly embodies the spirit of sustainability can feel like searching for a needle in a haystack. Enter cjmonsoon a company committed not just to profit but to purpose. With an innovative approach woven into its core mission, cjmonsoon is redefining what it means to grow responsibly while nurturing our planet.

At the heart of their operations lies an unwavering dedication to sustainable growth. This isn’t just about being green; it’s about creating lasting impacts for future generations. As we dive deeper into how cjmonsoon balances profitability with ecological responsibility, you’ll discover inspiring stories and actionable insights that can help pave the way for other businesses eager to make a difference. Join us as we explore this fascinating journey toward harmony between commerce and conservation!

Understanding sustainable growth and its importance

Sustainable growth is about striking a balance. It’s not just about profit; it encompasses environmental stewardship and social responsibility. Businesses today face increasing pressure to adapt their practices for our planet’s wellbeing.

This approach ensures that resources are used efficiently, minimizing waste while maximizing potential. A sustainable model leads to long-term resilience in an ever-changing market landscape.

Moreover, consumers are becoming more conscious of their choices. They prefer brands that prioritize sustainability. This shift affects purchasing decisions across various sectors.

Investing in sustainable growth can enhance brand loyalty and attract new customers. It fosters innovation as companies seek greener solutions, creating opportunities rather than limitations.

Understanding the importance of sustainable growth means recognizing its multifaceted benefits not just for businesses but for society and the environment at large. Embracing this concept paves the way toward a thriving future where everyone can succeed together.

How cjmonsoon incorporates sustainability in their business model?

cjmonsoon integrates sustainability at the core of its business model. The company prioritizes eco-friendly materials in their production processes. They carefully select suppliers who share a commitment to environmental responsibility.

Energy efficiency is another key aspect. By utilizing renewable energy sources, cjmonsoon minimizes its carbon footprint. This proactive approach not only benefits the planet but also reduces operational costs.

Waste reduction is central to their strategy as well. Through innovative recycling programs, cjmonsoon ensures that less material ends up in landfills. Employees are engaged and trained on sustainable practices, fostering a culture of awareness throughout the organization.

Community involvement plays a vital role too. cjmonsoon collaborates with local organizations for clean-up drives and education initiatives about sustainability. This creates a ripple effect, inspiring others to adopt environmentally friendly behaviors while strengthening community ties.

Success stories from cjmonsoon’s sustainable practices

One standout success story from cjmonsoon is its partnership with local farmers. By sourcing ingredients directly, they not only support the community but also reduce carbon footprints associated with transportation.

Their innovative water conservation techniques have made a significant impact. Through rainwater harvesting systems, cjmonsoon has dramatically decreased water usage in their operations. This initiative sets a benchmark for other businesses to follow.

Additionally, the launch of eco-friendly packaging has resonated well with consumers. By eliminating plastic and opting for biodegradable materials, they’ve significantly minimized waste while still maintaining product integrity.

These practices are more than just initiatives; they’re part of a broader commitment to environmental stewardship that drives customer loyalty and enhances brand reputation. Each small victory contributes to a larger narrative of sustainable innovation at cjmonsoon.

Future goals for sustainable growth at cjmonsoon

cjmonsoon is setting its sights on ambitious goals for sustainable growth. The company aims to enhance its eco-friendly practices by further reducing carbon emissions in the next five years.

Investing in renewable energy sources stands at the forefront of their strategy. This transition reduces operating expenses while supporting worldwide sustainability initiatives.

Engaging local communities plays a crucial role in cjmonsoon’s vision. By fostering partnerships, they plan to bolster awareness and education around environmentally responsible practices.

Innovation remains a key focus too. They are exploring cutting-edge technologies that can streamline processes while minimizing waste.

By prioritizing these initiatives, cjmonsoon envisions becoming a leader in sustainability within its industry, inspiring other businesses to follow suit and champion environmental responsibility.

Tips for businesses looking to implement sustainability

Start small. Implementing sustainability doesn’t require a complete overhaul overnight. Choose one area, like reducing plastic use or optimizing energy efficiency.

Engage your team. Encourage employees to share ideas and take ownership of sustainable initiatives. Collaboration can spark innovative solutions.

Set measurable goals. Define clear objectives for your sustainability efforts, whether that’s lowering waste by a certain percentage or increasing the use of renewable resources.

Communicate transparently with customers about your practices. Build trust by sharing both successes and challenges in your journey toward sustainability.

Consider partnering with local organizations focused on environmental issues. These collaborations can amplify impact and foster community support for shared goals.

Stay informed about industry trends in sustainability practices. Regularly update strategies to ensure relevance and effectiveness as new technologies emerge and consumer preferences evolve.

Evaluate progress regularly to adjust tactics as needed, ensuring ongoing commitment to sustainable growth without losing sight of company values.

Conclusion and call to action for supporting sustainable businesses like cjmonsoon

Supporting sustainable businesses like cjmonsoon is more important than ever. The commitment to sustainability not only contributes to a healthier planet but also drives innovation and economic growth. By choosing to engage with companies that prioritize ecological responsibility, consumers can participate in a larger movement towards environmental stewardship.

Consider making small changes in your purchasing decisions. Opt for products from brands that align with sustainable practices, just like cjmonsoon does. Your choices matter, and they can influence other businesses to adopt greener initiatives.

Whether you’re a consumer or an entrepreneur, supporting sustainability is crucial for our shared future. Together, we can create a world where business success aligns harmoniously with ecological well-being. Explore the offerings of cjmonsoon today and join the journey toward sustainable growth!

BUSINESS

Eschopper: Where Tech Meets Modern Commerce

Introduction to Eschopper

Welcome to the future of shopping, where cutting-edge technology meets an unparalleled consumer experience. Eschopper is revolutionizing the way we shop by seamlessly blending modern commerce with innovative tech solutions. Imagine a platform that understands your needs and preferences, allowing you to make informed decisions and enjoy a unique shopping journey. Whether you’re a savvy shopper or a business owner looking for new avenues to connect with customers, Eschopper has something special in store for you. Dive into this article as we explore how Eschopper is changing the landscape of retail and what it means for consumers and businesses alike.

The Technology Behind Eschopper

Eschopper leverages cutting-edge technology to redefine online shopping. At its core, a robust algorithm analyzes customer preferences and behaviors, delivering personalized recommendations that resonate with individual shoppers.

The platform employs advanced machine learning techniques. These algorithms adapt in real-time based on user interactions, ensuring that the shopping experience evolves with each visit. This creates a seamless interface where products are tailored to fit unique tastes.

Additionally, Eschopper integrates secure payment gateways powered by encryption technologies. This guarantees consumer data is protected during transactions, fostering trust between buyers and sellers.

Mobile optimization plays a critical role as well. With an intuitive app designed for swift navigation, users can shop anywhere at any time without hassle or confusion. The blend of these technologies positions Eschopper not just as an e-commerce platform but as an innovative solution for modern retail challenges.

How Eschopper is Changing the Way We Shop?

Eschopper is redefining shopping by merging technology with convenience. It offers a seamless experience where consumers can browse, compare, and purchase products effortlessly.

With its user-friendly interface, shoppers navigate through categories quickly. Advanced search features help users find exactly what they need in seconds. No more endless scrolling through irrelevant items.

Personalization plays a key role as well. Eschopper uses data analytics to tailor recommendations based on individual preferences and past purchases. This means each shopper receives suggestions that resonate with their unique tastes.

Moreover, real-time inventory updates ensure customers know what’s available instantly. There’s no waiting or uncertainty about stock levels just straightforward access to the latest products.

The integration of secure payment options adds another layer of comfort for buyers. Security concerns are minimized while enhancing the overall shopping experience.

Benefits of Using Eschopper for Consumers

Eschopper offers a seamless shopping experience that prioritizes convenience. Consumers can browse and purchase products from the comfort of their homes, eliminating the need for crowded stores.

The platform features advanced search algorithms, making it easy to find exactly what you’re looking for. Personalized recommendations based on browsing habits enhance the shopping journey further.

With Eschopper, consumers enjoy real-time access to exclusive deals and promotions. This allows you to spend less while still enjoying high standards and diverse choices.

Security is paramount in online shopping, and Eschopper employs robust measures to protect customer data. Shoppers can feel confident knowing their transactions are safe.

Additionally, fast shipping options ensure that customers receive their purchases promptly. With just a few clicks, items arrive at your doorstep without delay giving you more time for what matters most in life.

Benefits of Using Eschopper for Businesses

Eschopper offers businesses a streamlined approach to online retailing. By integrating cutting-edge technology, it simplifies inventory management and order processing. This efficiency directly translates into cost savings.

The platform allows for real-time analytics. Businesses can monitor sales trends and customer preferences, tailoring their services accordingly. Understanding the market dynamics helps in making informed decisions.

Additionally, Eschopper enhances customer engagement through personalized shopping experiences. Features like tailored recommendations attract more buyers and boost conversion rates.

Moreover, the user-friendly interface makes onboarding easy for employees. Less training time means that staff can focus on driving sales rather than learning complex systems.

With Eschopper, businesses also benefit from scalability. Whether a small startup or an established enterprise, the platform grows with your needs without compromising performance or quality of service.

Customer Success Stories and Testimonials

Eschopper has transformed the shopping experience for many users. One customer, Sarah, shared how effortless it became to find high-quality products at competitive prices. With just a few clicks, she discovered brands she’d never heard of before.

Another user, Mark, highlighted Eschopper’s intuitive interface. He loved how easy it was to navigate through various categories and quickly locate what he needed. His shopping time decreased significantly, allowing him to focus on other important tasks.

Businesses are also singing praises. A local boutique reported increased sales after joining Eschopper’s platform. They reached new customers who appreciated their unique offerings but wouldn’t have found them otherwise.

Testimonies flood in daily as more shoppers embrace this innovative approach to commerce. Each story reflects a growing satisfaction that underscores Eschopper’s impact on both consumers and businesses alike.

Future Plans and Innovations for Eschopper

Eschopper is on the brink of some exciting advancements. The team is actively working on integrating artificial intelligence to enhance user experience. This technology will personalize shopping experiences based on individual preferences and behaviors.

Additionally, augmented reality features are being developed for virtual try-ons. Imagine browsing through clothing or accessories and seeing how they look without leaving your home!

Sustainability initiatives are also at the forefront of Eschopper’s future plans. They aim to partner with eco-friendly brands, ensuring that consumers can shop responsibly.

Mobile app enhancements are underway too, aiming for seamless transactions and faster deliveries. With these innovations in place, Eschopper seeks to redefine what modern commerce looks like in the digital age. Each step taken reflects a commitment to evolving alongside consumer needs while embracing cutting-edge technology.

Conclusion: The Future of Shopping with Eschopper

Eschopper stands at the forefront of modern commerce, redefining how we shop and interact with technology. With its innovative platform, it seamlessly blends consumer needs with business efficiency. As retail continues to evolve, Eschopper is committed to adapting and enhancing user experiences.

The future holds exciting prospects for both consumers and businesses alike. Enhanced personalization features may emerge, allowing shoppers to find products tailored just for them more quickly than ever before. Businesses will benefit from advanced analytics that provide deeper insights into customer behavior.

As Eschopper grows, its community will expand too fostering a marketplace where innovation thrives and connections flourish. This journey is not only about transactions; it’s about creating relationships between brands and their customers in meaningful ways.

Embracing the changes brought by platforms like Eschopper signals a pivotal shift in shopping dynamics. Both consumers seeking convenience and businesses aiming for growth can look forward to an evolving landscape where tech-driven solutions enhance every experience. The possibilities are vast as we step boldly into this new era of shopping powered by Eschopper’s vision for the future.

BUSINESS

Onnilaina: Trust-Driven Digital Lending Model

Introduction to Onnilaina

In a world where financial transactions can often feel impersonal and daunting, Onnilaina emerges as a beacon of trust in the lending landscape. This innovative platform leverages digital technology to reshape how borrowers and lenders connect. Gone are the days of lengthy paperwork and face-to-face meetings with banks; instead, Onnilaina offers a streamlined approach that puts trust at its core.

Imagine being able to secure funds or lend money without the traditional barriers that have long plagued the industry. With Onnilaina, this vision becomes reality. By prioritizing transparency and reliability, it creates an environment where both parties can engage confidently. Let’s dive deeper into how this transformative model is changing lives for borrowers and lenders alike while building genuine trust in every transaction.

Traditional lending vs. Onnilaina’s digital lending model

Traditional lending often relies on long processes and extensive paperwork. Borrowers face numerous hurdles, from credit checks to collateral requirements. This can make accessing funds a daunting experience.

Onnilaina flips this model on its head. By leveraging technology, it streamlines the entire lending process. With just a few clicks, borrowers can apply for loans without the stress of physical documentation.

Trust plays a pivotal role in Onnilaina’s approach. Instead of solely focusing on credit scores, it considers various data points that paint a fuller picture of an applicant’s reliability.

In contrast to traditional methods, which may take days or weeks for approval, Onnilaina offers real-time assessments. This agility opens doors for many who might otherwise be overlooked by conventional lenders.

For both parties involved—borrowers seeking assistance and lenders looking to invest—this digital model creates opportunities rooted in transparency and efficiency.

How does Onnilaina work?

Onnilaina operates through a seamless online platform, connecting borrowers with lenders directly. This eliminates the traditional middleman and streamlines the lending process.

Borrowers start by creating a profile, providing essential information about their financial needs. They can specify loan amounts and repayment terms that suit them best.

Lenders review these profiles and decide whom to fund based on trust metrics and borrower credibility. This system allows for personalized lending experiences tailored to individual circumstances.

Once matched, transactions are secured electronically, ensuring safety for both parties involved. Borrowers receive funds quickly while lenders earn attractive returns on their investments.

The entire experience emphasizes transparency, giving users real-time updates throughout the lending journey. Trust is built right into every step of Onnilaina’s model, fostering confidence among all participants in this innovative ecosystem.

Benefits of using Onnilaina for borrowers

Onnilaina offers a refreshing alternative for borrowers seeking financial solutions. The digital platform simplifies the lending process, making it accessible and efficient. With just a few clicks, users can apply for loans without the hassle of traditional paperwork.

Borrowers enjoy clear conditions and attractive interest rates. This clarity fosters confidence in decision-making, allowing individuals to understand their commitments fully before proceeding.

Another advantage is flexibility. Onnilaina accommodates various borrowing needs whether it’s for emergencies or planned expenses. Users can choose loan amounts that suit their specific situations.

Additionally, the quick approval process means funds are often available much faster than with conventional lenders. This speed helps borrowers address urgent financial needs without long waiting periods.

Moreover, Onnilaina emphasizes personalized customer support, ensuring that borrowers receive guidance throughout their journey.

Benefits of using Onnilaina for lenders

Lenders find a wealth of advantages when using Onnilaina. The platform simplifies the lending process, allowing for quick assessments and approvals.

With advanced algorithms in place, lenders can evaluate potential borrowers efficiently. This reduces time spent on paperwork and enables faster decision-making.

Additionally, Onnilaina fosters transparency throughout the lending journey. Lenders receive detailed information about borrowers’ profiles, enhancing their confidence in each transaction.

Risk management is another significant benefit. The model incorporates trust metrics that help reduce defaults and improve investment security.

By engaging with a diverse pool of borrowers, lenders can also achieve better returns on their investments. This accessibility broadens opportunities beyond traditional channels.

Being part of a trust-driven ecosystem enhances lender reputation within the community. Positive experiences contribute to building long-term relationships with borrowers who value reliability and integrity.

How trust is built into Onnilaina’s model?

Trust is the cornerstone of Onnilaina’s digital lending model. It begins with transparency. Borrowers and lenders can see all terms clearly, eliminating confusion.

Next, Onnilaina employs robust verification processes. This ensures that both parties are who they claim to be. By validating identities and financial backgrounds, risk is minimized for everyone involved.

Onnilaina also fosters a community atmosphere through user reviews and ratings. Borrowers share experiences while lenders gain insights into potential risks or rewards associated with each loan.

The platform prioritizes secure transactions as well. Advanced encryption technology safeguards personal information and funds during every step of the process.

Customer support plays a vital role in building trust. Quick responses to inquiries help maintain positive relationships between users, reinforcing confidence in the platform’s reliability.

Success stories of borrowers and lenders on Onnilaina

Onnilaina has transformed lives through its innovative lending model. Many borrowers have shared their journeys of financial empowerment after accessing funds quickly and easily.

Take Sarah, for example. She needed a small loan to start her bakery business. With Onnilaina’s streamlined process, she secured funding within days, allowing her dreams to rise like the dough in her oven.

Lenders also celebrate their experiences on the platform. James invested his savings with confidence, knowing he could support local entrepreneurs while earning attractive returns.

Each story reflects how Onnilaina fosters connections between individuals who trust each other. This sense of community strengthens both sides of the borrowing equation and cultivates a positive cycle of growth and opportunity.

These stories highlight more than just transactions; they illustrate real impact showing how trust can bridge gaps in traditional finance systems and create thriving relationships among users.

Future plans and expansion of Onnilaina

Onnilaina is poised for significant growth in the coming years. The focus is on expanding its footprint in both local and international markets. New partnerships with fintech companies will enhance their digital offerings.

The development of a mobile app is also on the horizon, making it easier for users to access services anytime, anywhere. This user-friendly approach aims to attract a younger demographic that values convenience.

Moreover, Onnilaina plans to introduce innovative features like personalized loan recommendations based on borrower behavior. This will foster an even stronger connection between lenders and borrowers.

Investments in advanced security measures are crucial as well. Ensuring trust remains at the forefront while navigating expansion efforts will help solidify Onnilaina’s reputation within the lending landscape.

With these initiatives, Onnilaina envisions becoming a leader in trust-driven digital lending solutions globally.

Conclusion: The impact of trust in the lending industry

The impact of trust in the lending industry cannot be overstated. Onnilaina stands as a testament to how digital innovation can reshape financial interactions. By fostering an environment built on transparency and reliability, it encourages both borrowers and lenders to engage with confidence.

Trust is not just a buzzword for Onnilaina; it’s woven into every facet of its operations. Borrowers find peace of mind knowing they are dealing with credible lenders who value their financial well-being. Lenders, on the other hand, benefit from a system that prioritizes security and accountability.

As more individuals embrace this model, the landscape of lending continues to evolve. Communities grow stronger when trust prevails in financial transactions. With Onnilaina leading the charge, there’s potential for a profound shift across the entire lending industry one where relationships thrive based on mutual respect and understanding rather than mere numbers or interest rates.

This new paradigm invites everyone to rethink how we approach borrowing and lending in today’s digital age. It highlights that at the core of successful financial exchanges lies something far more valuable than capital trust.

HOME IMPROVEMENT12 months ago

HOME IMPROVEMENT12 months agoThe Do’s and Don’ts of Renting Rubbish Bins for Your Next Renovation

BUSINESS1 year ago

BUSINESS1 year agoExploring the Benefits of Commercial Printing

BUSINESS12 months ago

BUSINESS12 months agoBrand Visibility with Imprint Now and Custom Poly Mailers

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoDizipal 608: The Tech Revolution Redefined

HEALTH8 months ago

HEALTH8 months agoThe Surprising Benefits of Weight Loss Peptides You Need to Know

HEALTH8 months ago

HEALTH8 months agoYour Guide to Shedding Pounds in the Digital Age

HOME IMPROVEMENT8 months ago

HOME IMPROVEMENT8 months agoGet Your Grout to Gleam With These Easy-To-Follow Tips

HEALTH11 months ago

HEALTH11 months agoHappy Hippo Kratom Reviews: Read Before You Buy!