GENERAL

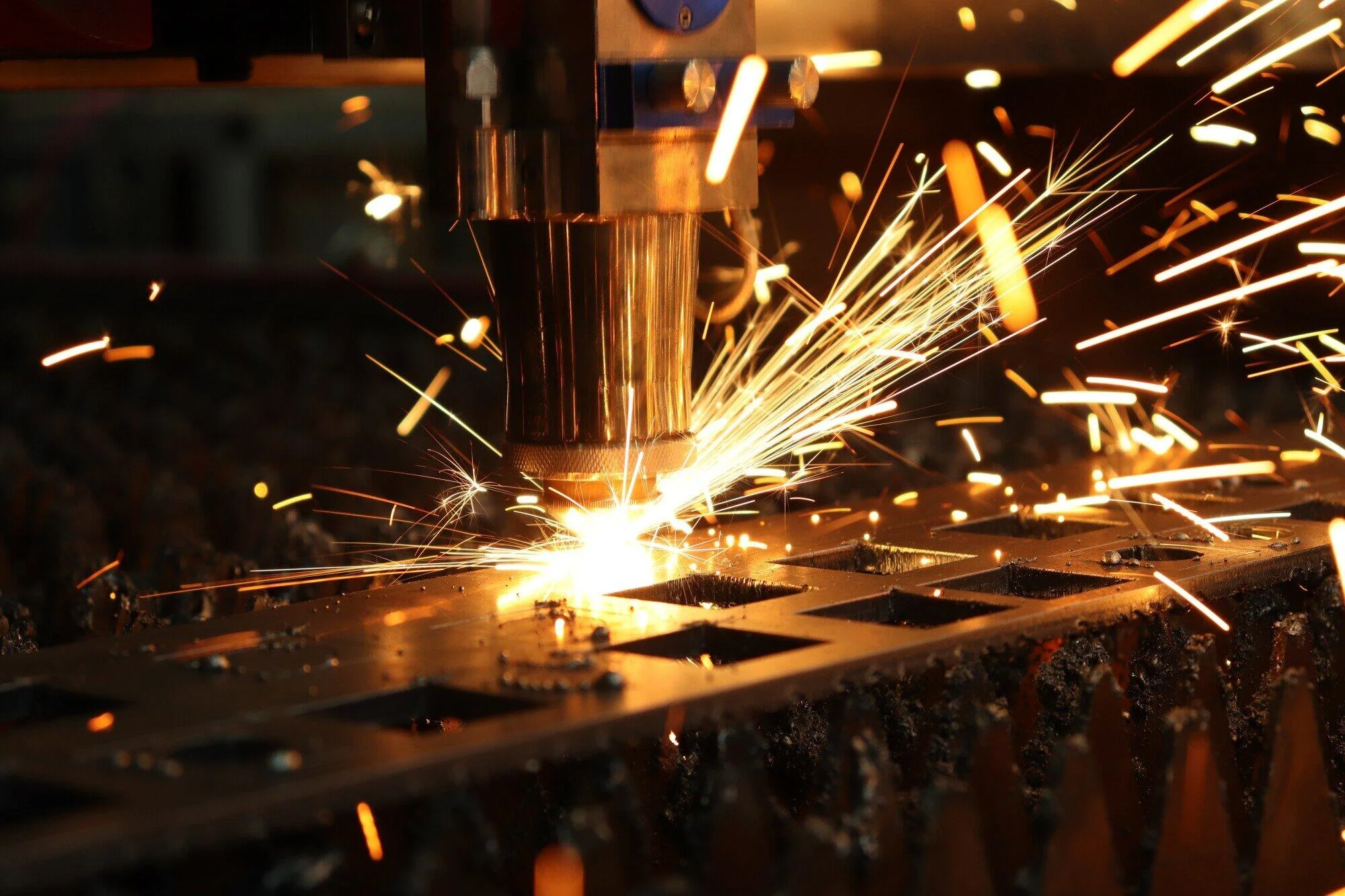

Exploring the Versatility and Durability of Stainless Steel Casting

Stainless steel casting is a standout choice for many industries. It combines strength, durability, and versatility.

This process creates parts that are resistant to corrosion, withstand high temperatures, and endure wear and tear. From medical equipment to aerospace components, the applications are endless.

Stainless steel casting ensures high-quality results. It is a preferred solution for manufacturing. In this blog, we will explore the benefits and uses of stainless steel casting, demonstrating why it is a top choice for many sectors. Dive in to learn how this method can meet various industrial demands.

What is Stainless Steel Casting?

Stainless steel casting is a process that involves pouring molten stainless steel into a mold to create complex shapes. This method is effective for producing parts that are:

- strong

- durable

- resistant to corrosion

To make smart choices about materials for different uses, it’s important to grasp this process. Stainless steel casting is used in a variety of industries because of its unique properties.

It’s not just about strength. It also offers excellent resistance to wear and tear, making it ideal for products that need to withstand harsh conditions. We’ll explore these properties in more detail as we go along.

The Importance of Versatility

Why is versatility so important in material choice? Simply put, the more versatile a material, the more applications it can be used for.

Stainless steel casting stands out in this regard. From automotive parts to kitchenware, its applications are virtually endless. The ability to cast metals into complex shapes allows for a wide range of uses.

This versatility means that it can meet your needs. It doesn’t matter if you’re in construction, automotive, or even art. Stainless steel casting can help. The process itself can be tailored to produce intricate designs or robust components, depending on what you need.

Durability That Stands the Test of Time

When it comes to durability, few materials can match stainless steel. It’s resistant to:

- rust

- corrosion

- extreme temperatures

This makes it an excellent choice for parts that need to last for years if not decades. Stainless steel casting produces parts that are not only strong but also long-lasting.

This toughness is key in construction and automotive. Components there often face tough conditions. Imagine having a car part that never rusts or a kitchen appliance that remains spotless year after year. That’s the power of stainless steel casting.

Applications in Various Industries

One reason to choose stainless steel casting is its many uses in different industries. Let’s take a closer look at some of these applications.

Automotive Industry

In the automotive industry, stainless steel casting is used to produce parts that need to be both strong and lightweight. It is great for parts like exhaust systems, engine components and parts, and structural elements because it lasts long and resists rust.

Aerospace Industry

The aerospace industry also relies heavily on stainless steel casting. Parts used in aircraft need to withstand extreme conditions. From high altitudes to rapid changes in temperature. The durability and resistance to corrosion make it an ideal material for these applications.

Household Items

Even in our homes, stainless steel casting plays a crucial role. Kitchen appliances, cutlery, and some furniture use stainless steel. They use it for its strength and beauty. The ability to cast it into various shapes and designs makes it a favorite in both functional and decorative items.

Advantages Over Other Materials

What sets stainless steel casting apart from other materials? Several key advantages make it the preferred choice for many applications.

Corrosion Resistance

One of the standout features of stainless steel is its resistance to corrosion. Unlike iron or regular steel, stainless steel doesn’t rust easily. This makes it ideal for applications exposed to moisture or chemicals. This property alone can extend the life of a product.

Strength and Hardness

Stainless steel is incredibly strong and hard, which means it can withstand significant stress and strain without deforming. This is particularly important in industries like construction and automotive, where components need to endure heavy loads and impacts.

Aesthetic Appeal

Beyond its functional advantages, stainless steel also has an aesthetic appeal. Its shiny, polished finish makes it a popular choice for decorative elements in both residential and commercial settings. Whether it’s a sleek kitchen appliance or a modern piece of furniture, stainless steel adds a touch of elegance.

Environmental Benefits

In today’s world, sustainability is more important than ever. Stainless steel casting offers several environmental benefits that make it a responsible choice.

Recyclability

Stainless steel is 100% recyclable, which means it can be reused indefinitely without losing its properties. This makes it an eco-friendly option for those looking to minimize their environmental impact.

Longevity

The long lifespan of stainless steel products means less frequent replacements and, consequently, less waste. This durability contributes to a more sustainable lifecycle for products made from this material.

Energy Efficiency

The production process for stainless steel casting can also be energy-efficient. Modern foundries often use advanced technologies to minimize energy consumption, making the entire process more sustainable.

Innovations in Stainless Steel Casting

The field of stainless steel casting is continually evolving, with new innovations making it even more versatile and durable.

Advanced Alloys

New alloys are being developed to enhance the properties of stainless steel. These advanced alloys offer improved strength, corrosion resistance, and even better aesthetics, making them suitable for a broader range of applications.

Precision Casting

Innovations in precision casting techniques allow for the production of highly detailed and intricate parts. This is particularly important in industries like aerospace and medical devices, where precision is critical.

Sustainable Practices

Sustainability is a growing focus in the industry. Foundries are adopting more sustainable practices, from using recycled materials to implementing energy-efficient processes. These efforts contribute to a more eco-friendly production process.

Enjoy the Versatility and Durability of Stainless Steel Now

Stainless steel casting is a popular choice for many industries because of its strong, durable, and versatile nature. It provides great protection against corrosion, looks good, and is kind to the environment as it can be recycled.

While it may be a bit pricey and tricky to cast, the advantages, in the long run, are worth it. Stainless steel casting is improving with eco-friendly methods, making it an excellent choice for a wide range of uses.. Opt for stainless steel casting for dependable, durable solutions.

For a variety of engaging topics, check out our other blog articles. Enjoy reading!

GENERAL

Demystifying Insurance Claims: Debunking 5 Common Misconceptions

Insurance claims can be a tricky maze to navigate, where unique regulations and circumstances come into play. Whether you’re dealing with a car accident, property damage, or personal injury, understanding the nuances of insurance claims is crucial to ensure you get the compensation you deserve. Unfortunately, misinformation often leads to misconceptions that can hinder your ability to receive fair reimbursement. This article will debunk five common misconceptions about insurance claims and shed light on why it’s wise to seek legal counsel from personal injuries attorneys for optimal outcomes.

Misconception #1: “Filing a Claim Means Premiums Will Skyrocket”

One prevalent myth is that filing an insurance claim will inevitably result in skyrocketing premiums. While it’s true that some insurers may raise rates after a claim, especially if you’re deemed at fault for an incident, not all claims lead to increased premiums. Some states have laws that prohibit insurers from raising rates based solely on claims filed for accidents where you were not at fault. Additionally, if you have a history of safe driving or few previous claims, your premiums may remain unaffected.

Misconception #2: “You Can Handle the Claim Process Alone”

Another misconception is that handling insurance claims independently is always the best approach. While it’s possible to navigate simple claims processes solo, more complex situations often benefit from professional assistance. For instance, if you’ve suffered severe injuries in a car accident or your insurance company is disputing your claim, consulting with personal injuries attorneys can provide invaluable guidance. They can advocate for your rights, negotiate with insurance adjusters, and ensure you receive fair compensation for medical bills, lost wages, and pain and suffering.

Misconception #3: “The Insurance Company Is Always on Your Side”

It’s essential to recognize that insurance companies are for-profit entities with their bottom line in mind. While they may advertise themselves as being on your side, their primary goal is to minimize payouts and protect their interests. Consequently, don’t assume that the initial settlement offer provided by your insurer is the best you can get. It’s often a starting point for negotiations, and having a legal professional review the offer can help you determine if it’s fair or if further action is warranted.

Misconception #4: “You Don’t Need Documentation for Your Claim”

Some individuals believe they can simply provide a verbal account of an incident to their insurer without supporting documentation. However, thorough documentation is essential to substantiate your claim and maximize your chances of receiving compensation. This includes gathering evidence such as photos of the accident scene, medical records documenting injuries, repair estimates for damaged property, and any other relevant information. The more evidence you can provide, the stronger your claim will be.

Misconception #5: “If Your Claim Is Denied, That’s the End of It”

Receiving a claim denial can be disheartening, but it doesn’t necessarily mean the end of the road. Many claims are initially denied or undervalued by insurance companies, often due to incomplete information or misinterpretation of policy terms. If your claim is denied, you have the right to appeal the decision and present additional evidence to support your case. In such situations, seeking legal guidance can be instrumental in navigating the appeals process and pursuing the compensation you’re entitled to.

Navigating the intricacies of insurance claims requires more than just a cursory understanding of the process. It demands a keen awareness of the common misconceptions that can hinder your ability to secure fair compensation. By dispelling these myths and embracing the reality that legal assistance may be necessary in certain situations, you empower yourself to advocate for your rights effectively.

GENERAL

5612425780: Safeguarding West Palm Beach Through General Alerts

In today’s fast-paced world, ensuring the safety and security of communities is paramount. One crucial tool in achieving this goal is the implementation of general alerts. In this article, we delve into the significance of general alerts in safeguarding West Palm Beach, with a focus on the role of 5612425780 in this endeavor.

Understanding General Alerts

General alerts are notifications issued to the public to convey important information regarding safety, security, or emergency situations. These alerts serve as a vital communication channel between authorities and the community, enabling timely responses and actions to mitigate risks.

The Role of 5612425780 in Safeguarding West Palm Beach

At the forefront of safeguarding West Palm Beach is 5612425780, a comprehensive alert system designed to keep residents informed and safe. Whether it’s severe weather warnings, traffic advisories, or public safety alerts, 5612425780 ensures that vital information reaches residents promptly.

How 5612425780 Works

5612425780 operates through a multi-channel approach, utilizing text messages, emails, phone calls, and social media platforms to disseminate alerts. Users can customize their preferences to receive alerts specific to their location and interests, ensuring relevant information reaches them when it matters most.

Also Read: UNDERSTANDING THE MYSTERY BEHIND CALLS FROM 02045996870

Benefits of General Alerts

The implementation of general alerts brings forth numerous benefits to the community of West Palm Beach. By keeping residents informed and aware, these alerts facilitate better preparedness and response during emergencies. Additionally, they help minimize risks and enhance overall safety levels.

Key Features of 5612425780

5612425780 boasts several key features that set it apart as a leading general alert system. From its user-friendly interface to its real-time updates and geo-targeted alerts, 5612425780 ensures that residents receive accurate and pertinent information promptly.

Importance of Community Participation

Active participation from the community is crucial in maximizing the effectiveness of general alerts. By staying informed and adhering to safety guidelines outlined in alerts, residents contribute to the overall safety and well-being of their neighborhoods.

Examples of General Alerts

In West Palm Beach, general alerts have proven instrumental in various scenarios, including hurricane warnings, road closures, and public health advisories. These real-life examples underscore the importance of having a robust alert system in place.

Also Read: TRENDZGURUJI.ME CYBER INFO: UNVEILING THE CYBERSECURITY REALM

Ensuring Accessibility

Efforts must be made to ensure that general alerts reach all members of the community, including those with disabilities or language barriers. Utilizing diverse communication channels and providing accessible formats are essential steps in achieving inclusivity.

Challenges and Solutions

Despite the benefits, implementing general alert systems may encounter challenges such as technological limitations or communication barriers. However, through collaborative efforts and innovative solutions, these challenges can be addressed to optimize the effectiveness of alert systems.

Future of General Alerts in West Palm Beach

As technology continues to advance, the future of general alerts in West Palm Beach looks promising. With advancements in artificial intelligence and data analytics, alert systems can become even more precise and proactive in addressing emerging threats.

Case Studies

Examining successful implementations of general alert systems in other cities provides valuable insights for West Palm Beach. By learning from best practices and adapting strategies to local needs, the city can further enhance its alert capabilities.

Feedback and Improvement

Continuous feedback from residents is essential for the improvement of general alert systems. By soliciting input and addressing concerns, authorities can ensure that alert systems remain effective and responsive to community needs.

Conclusion

In conclusion, general alerts play a vital role in safeguarding West Palm Beach by keeping residents informed and prepared. With the implementation of innovative systems like 5612425780, the city can enhance its resilience and responsiveness to various challenges.

Also Read: TYPES OF NETWORK SECURITY PROTOCOLS YOU NEED TO KNOW

FAQs

Q: What types of alerts does 5612425780 provide?

Ans: 5612425780 provides a wide range of alerts, including weather advisories, traffic updates, and public safety notifications.

Q: Can I customize the alerts I receive?

Ans: Yes, users can customize their alert preferences based on their location and interests.

Q: Is 5612425780 accessible to individuals with disabilities?

Ans: Efforts are made to ensure that 5612425780 is accessible to all members of the community, including those with disabilities.

Q: How can I provide feedback on the alert system?

Ans: Residents can provide feedback on 5612425780 through the official website or designated feedback channels.

Q: Are general alerts issued in multiple languages?

Ans: Efforts are made to provide alerts in multiple languages to ensure inclusivity and accessibility.

GENERAL

When to Replace Forklift Tires: A Comprehensive Guide

Forklifts are indispensable tools in many industries, facilitating the movement of heavy goods with ease and efficiency. Central to the safe and efficient operation of these machines are their tires, like the Helmar forklift tires. Quality forklift tires are defined by their durability and reliability, essential attributes that ensure long-term performance and safety. High-quality tires resist wear and tear, maintaining their integrity even under heavy loads and frequent use.

Importance of Quality Forklift Tires

The significance of quality forklift tires cannot be overstated. They are critical in ensuring safety, efficiency, and productivity within warehouses, factories, and distribution centers. These tires are the foundation upon which the entire operation rests, bearing the weight of heavy loads and providing traction on various surfaces. Without reliable tires, the risk of accidents and disruptions to workflow increases significantly.

Moreover, quality tires contribute to lower maintenance costs and reduced downtime, allowing operations to run smoothly and uninterrupted. Investing in high-quality forklift tires is an investment in the overall success and functionality of industrial operations.

Choosing the Right Tires for Your Forklift

Selecting the appropriate tires for your forklift is a decision that should not be taken lightly. Several factors must be considered to ensure optimal performance and longevity. One of the primary considerations is the type of forklift and its intended use. Different forklift models require specific tire types to accommodate load capacities and operational environments.

Additionally, the surface on which the forklift will primarily operate influences tire selection. Smooth, indoor surfaces may necessitate different tires than rough, outdoor terrain. Understanding these factors is crucial in choosing tires that can withstand the demands of the working environment.

Features of Quality Forklift Tires

Quality forklift tires like those of Helmar forklift tires exhibit several key features that differentiate them from inferior alternatives. Durability is paramount, as tires must endure constant use and exposure to heavy loads without premature wear and tear. High-quality materials and superior construction contribute to the longevity of these tires, ensuring consistent performance over time.

Furthermore, reliability is a hallmark of quality forklift tires. They offer dependable traction and stability, allowing for smooth operation and precise maneuverability. This reliability enhances safety in the workplace, reducing the risk of accidents and injuries associated with tire malfunctions or failures.

Signs That It’s Time to Replace Forklift Tires

Despite their durability, forklift tires are not immune to wear and degradation. Recognizing the signs that indicate the need for tire replacement is essential for maintaining workplace safety, efficiency, and productivity.

- Tread Wear: One of the most prominent indicators that forklift tires require replacement is significant tread wear. Worn treads diminish traction and stability, increasing the risk of accidents, especially when carrying heavy loads or operating on uneven surfaces. In addition to compromising safety, worn treads reduce efficiency and productivity in industrial operations. Promptly replacing tires exhibiting extensive tread wear is essential for maintaining optimal performance and mitigating the potential for workplace accidents. Regular inspections and proactive maintenance practices can help identify worn tires before they compromise operational safety and effectiveness.

- Cracks or Cuts: Regular inspection of forklift tires is paramount to identifying potential hazards that compromise operational safety. Among the critical signs of deterioration are cracks or cuts in the rubber, indicative of underlying structural weaknesses. If left unaddressed, these imperfections can escalate into significant safety risks, culminating in sudden tire failures during operation. Such failures not only endanger personnel but also disrupt workflow efficiency. Timely detection and remediation of these issues are imperative to maintaining a secure working environment and optimizing forklift performance. Hence, incorporating routine tire inspections into operational protocols is essential for preempting avoidable accidents and downtime.

- Bulges or Blistering: Bulges or blisters on the sidewalls of forklift tires indicate internal damage or weakness. Continued use of tires with these abnormalities poses a severe safety hazard and should prompt immediate replacement. Such deformities compromise the tire’s structural integrity, increasing the risk of blowouts or sudden failures during operation. In addition to jeopardizing the safety of personnel and equipment, neglected bulges or blisters can escalate maintenance costs and downtime. Timely identification and replacement of affected tires are essential for mitigating these risks and maintaining optimal safety standards in industrial environments.

- Uneven Wear Patterns: Uneven wear patterns across the surface of the tire suggest alignment issues or improper tire inflation. Addressing these issues promptly can prevent further damage to the tires and prolong their lifespan.

Knowing when to replace forklift tires is crucial for maintaining safety, efficiency, and productivity in industrial settings. Quality tires are essential for ensuring the reliable performance of forklifts, offering durability, traction, and stability under demanding conditions. By understanding signs of tire wear and degradation, operators can proactively replace tires before they compromise workplace safety or disrupt operations. Investing in high-quality forklift tires is a prudent decision that pays dividends in performance, longevity, and cost-effectiveness.

BUSINESS1 year ago

BUSINESS1 year agoExploring the Benefits of Commercial Printing

HOME IMPROVEMENT12 months ago

HOME IMPROVEMENT12 months agoThe Do’s and Don’ts of Renting Rubbish Bins for Your Next Renovation

BUSINESS12 months ago

BUSINESS12 months agoBrand Visibility with Imprint Now and Custom Poly Mailers

HEALTH8 months ago

HEALTH8 months agoThe Surprising Benefits of Weight Loss Peptides You Need to Know

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoDizipal 608: The Tech Revolution Redefined

HEALTH7 months ago

HEALTH7 months agoYour Guide to Shedding Pounds in the Digital Age

HOME IMPROVEMENT8 months ago

HOME IMPROVEMENT8 months agoGet Your Grout to Gleam With These Easy-To-Follow Tips

HEALTH11 months ago

HEALTH11 months agoHappy Hippo Kratom Reviews: Read Before You Buy!