BUSINESS

How to Fix a Failed ERP Implementation for Your Manufacturing Organization?

ERP implementation failure in any company, including manufacturing organization, is the worst-case scenario. The implementation team will deploy the best strategies to avoid ERP implementation failure.

However, even after giving the best efforts, the implementation team sometimes fails to deploy the ERP system effectively. Often, troubled implementations are behind schedule, cost more than the pre-determined budget, or fail to deliver expected business benefits. The aftermath of such project failure can disrupt operations in the manufacturing unit and demoralize employees at every level.

You can restore your manufacturing business confidence and re-align the production projects with business priorities by deploying a successful Manufacturing ERP Software recovery plan. This article discusses the causes of ERP implementation failure and how to fix it.

Causes of ERP Implementation Failure

Lack of clear goals and objectives

Without determining what you want your manufacturing business to achieve with an ERP system, you will find it difficult to properly plan, implement, and measure the system’s success.

Insufficient training and support

Employees should be properly trained and supported to implement and use the new ERP system effectively. Without adequate training and support, employees might struggle to implement and use the platform, leading to adoption issues and poor productivity.

Inadequate data migration

Migrating business data from traditional database systems to the new ERP platform can be complex and time-consuming. If the data migration process is not carried out properly, it can result in data loss, errors, and inaccuracies.

Customization issues

Many ERP systems designed for the manufacturing industry are highly configurable, but not appropriately customized can lead to compatibility issues and system errors.

Inadequate testing

Testing is vital to successfully implement ERP software, as it helps identify and resolve potential issues before the system goes live. Without deploying adequate testing techniques, you can’t discover potential issues until after the ERP system is in production, leading to downtime and other problems.

How Can You Fix a Failed ERP Implementation?

Following these steps can help you fix a failed ERP implementation in your manufacturing organization:

Identify the root cause of the failure

You should thoroughly analyze the ERP implementation process to determine what went wrong. It might include reviewing project documentation, interviewing stakeholders, and analyzing system logs.

Create a plan to address identified issues

Once you have identified the root cause of the ERP implementation failure, create a plan to address the identified issues. It might include revising the project scope, adding additional resources to the implementation project, or revisiting the implementation timeline.

Communicate with stakeholders

You should inform the stakeholders involved in the ERP implementation project about the progress of the recovery effort and keep them engaged in the recovery process as much as possible.

Identify and mitigate risk

Identifying the risks associated with the recovery effort beforehand is recommended. In addition, try to mitigate them as early as possible. It might include the risks related to data integrity, compliance, or system availability.

Continuously monitor the recovery progress

Your job doesn’t end with deploying the recovery plan and strategies. Instead, you should continuously monitor the progress of your recovery effort and make adjustments as and when needed to fix ERP implementation failure successfully.

Consider professional help

Your in-house employees might not be capable enough to fix the ERP implementation failure. In such a case, consider hiring professional consultants specialized in implementing the erp for manufacturing companies and helping you with your recovery efforts.

Post-implementation review

After successfully implementing the ERP system, you should conduct a thorough review to identify the lessons that you can apply in future ERP implementation projects.

Concluding Thoughts

Implementing an ERP system is crucial to automate, streamline, and optimize all manufacturing company operations, functions, and activities. With a technologically advanced ERP system, you can do everything from purchase and procurement to inventory and human resource management within less time, effort, and cost.

However, some manufacturing units fail to implement ERP systems successfully, impacting business productivity. It can be a long and arduous road to recover from a failed ERP system implementation, but getting your manufacturing company back on track is crucial. Following the above-discussed tips can help you recover from the ERP implementation failure. Don’t hesitate to make internal business process changes to deploy the ERP system and leverage its functionality efficiently.

Eresource infotech Pvt ltd is leading ERP Software Company In India. We provides ERP Software for manufacturing, construction, process manufacturing, transportation, trading and distribution industries.

BUSINESS

Tips for Choosing the Right Yard Waste Dumpster Rental

When it comes to managing yard waste, having the right dumpster rental can make a world of difference. Whether you’re tackling a landscaping project or simply cleaning up your outdoor space, having a convenient and efficient way to dispose of yard waste is essential.

With numerous options available, it’s important to know what to look for when choosing a yard waste dumpster rental.

Here are some valuable tips to help you make the right decision.

Assess Your Needs

Before you dive into searching for a yard waste dumpster rental, pause for a second to think about what you need. Think about how much yard waste you think you’ll end up with and the size of the stuff you’re tossing out. This will give you a good idea of what size dumpster you should go for. Rental services usually have different sizes to choose from, so knowing your needs will make picking one a breeze.

Research Local Providers

Before selecting a yard waste dumpster rental, it’s crucial to research local providers thoroughly. Explore this dumpster rental service in Delaware for insights on what to consider when choosing a rental company near you. Delve into reviews, compare pricing, and evaluate services provided. Ensuring you secure the most advantageous deal available while upholding quality is paramount.

Consider Sustainability

Going green is not only good for the environment, but it can also save you money on your rental. When searching for a yard waste dumpster rental, consider asking if they have environmental considerations in their waste management process or if they recycle the waste they collect. This will not only reduce your carbon footprint but may also result in lower fees.

Consider Pricing and Terms

When you’re checking out various yard waste dumpster rental choices, make sure to think about the pricing and terms. Look for clear pricing options with no sneaky fees, and ask about any extra charges for delivery, pickup, or going over weight limits.

Also, keep an eye on how long you can rent it and any rules about what kind of yard waste you can toss in. Knowing the ins and outs of the rental deal will help you dodge surprises and make sure your rental goes without a hitch.

Choose the Right Size

Choosing the perfect dumpster size is key for handling yard waste like a pro. If it’s too small, you’ll end up with overflow and extra charges; too big, you’re overspending. Think about how much waste you’ll have and pick a dumpster size that’s just right. Rental services usually have various options, so you can find the one that suits your needs best.

Prioritize Sustainability

When you’re renting a yard waste dumpster, think about going green. Check out dumpster rental services that give eco-friendly disposal choices like composting or recycling yard waste whenever they can. By picking a provider that cares about sustainability, you’re not just getting rid of waste, you’re helping out the planet too.

Making the Right Yard Waste Dumpster Rental Choice

Picking the perfect yard waste dumpster rental is a must for handling outdoor projects and keeping your outdoor area neat. By figuring out what you need, checking out local options, thinking about costs and terms, finding the right size, and focusing on sustainability, you can make sure renting goes smoothly.

Whether you’re sprucing up your yard or doing some landscaping, choosing the best dumpster rental service in your area will help you manage your yard waste well and in an eco-friendly way.

Share this article and other related content with your fellow readers as you continue exploring the articles on this site.

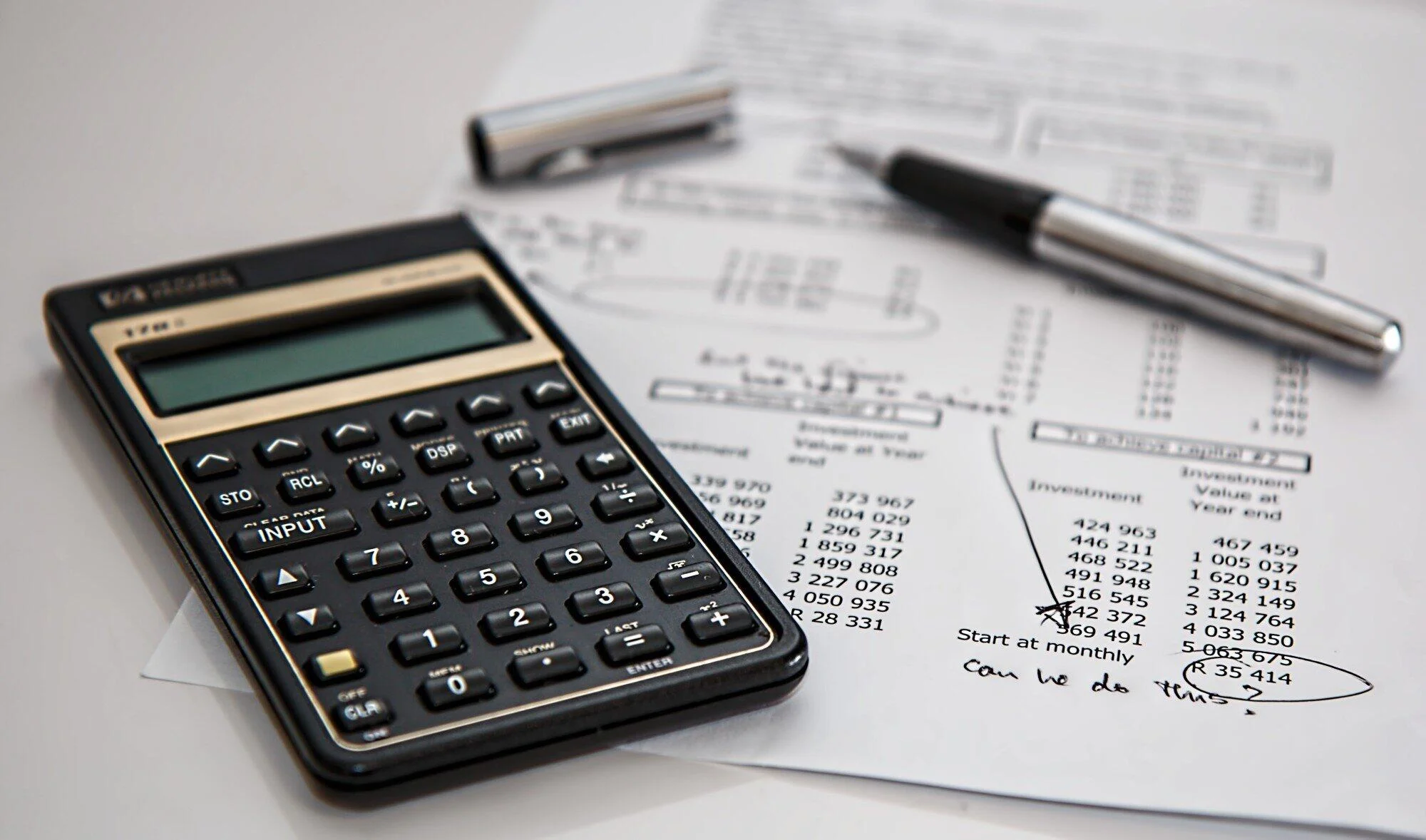

FINANCE

The Benefits of Utilizing Expert Tax Services for Managing Your 529 Plan

Navigating the complexities of a 529 Plan can feel overwhelming. Especially when considering tax implications. That’s where expert tax services come into play.

But what makes a tax accountant invaluable in this scenario? They bring clarity to intricate tax laws and regulations. By doing so, they ensure you’re compliant and maximizing your savings.

Their guidance becomes a beacon, illuminating the path to financial efficiency. In managing your 529 Plan, the expertise of a tax accountant is indispensable. They turn a daunting task into a manageable and strategic financial decision.

Understanding the Tax Benefits of a 529 Plan

529 plan is a type of savings plan that allows you to invest funds for future education expenses without incurring federal taxes on earnings or withdrawals. Many states offer additional tax incentives for contributing to a 529 Plan.

These can include deductions or credits on state income taxes. It makes it an even more attractive option for families saving for education expenses. Yet, it’s crucial to understand the specific tax benefits of your state’s plan.

It is where expert tax services come in. They have an in-depth understanding of state-specific tax laws and regulations. They take advantage of all available tax benefits.

The Expertise of Tax Accountants in Maximizing Savings

One of the benefits of utilizing expert tax services for your 529 education savings plans is their ability to maximize your savings. Tax accountants have a deep understanding of tax laws and regulations, including those specific to 529 Plans. They can help you navigate the complex tax implications of your contributions, earnings, and withdrawals from the plan.

This knowledge allows them to identify opportunities for tax savings. It ensures that you are compliant with all tax laws related to 529 education savings plans.

By leveraging their expertise, you can make informed decisions. It optimizes your financial benefits and secures your future educational savings.

Strategic Planning for Your 529 Plan

An expert tax service can help you develop a strategic plan for your 529 Plan. They can analyze your financial situation and determine the most helpful ways to contribute, invest, and withdraw funds from the plan.

Tax accountants can also guide how to coordinate 529 Plan contributions with other education-related tax benefits. These includes the following:

- American Opportunity Tax Credit

- Lifetime Learning Credit

Peace of Mind and Ongoing Support

Managing a 529 Plan can be a time-consuming and complex task. By utilizing expert tax services, you can have peace of mind knowing that your plan is being managed efficiently and effectively.

Tax accountants can also provide ongoing support and guidance as your financial situation changes or as new tax laws are implemented. It allows you to focus on other important aspects of your life while still ensuring that your 529 Plan is being managed in the most beneficial way possible.

Discovering the Benefits of Expert Tax Services

Expert tax services make 529 Plans manageable. They decode complex tax issues, revealing paths to savings. Their insight ensures compliance and optimizes your investment.

Affordable tax service transforms daunting tasks into strategic success. It’s about maximizing benefits while minimizing stress. Choose expert tax services for peace of mind.

They safeguard your educational savings, ensuring future success. Remember, investing in expert advice pays dividends in financial health.

Did you find this article helpful? If so, check out the rest of our site for more informative content.

REAL ESTATE

The Cost of Inflation in Construction

Since 2022 inflation has been driving up costs for just about everything, from bread to gasoline to construction costs and manufacturing. At just about every level, cost increases from 10 to 200 percent have been realized, sometimes adding three to four layers onto the original cost from the producer before reaching the final end user or customer. Construction in particular has been significantly hammered by inflation in multiple areas, depending on so many different supplies, skills, trades and products to complete a project. That cost increase ultimately has to get passed on to the commercial or industrial customer who may not be so willing to take on such increases if they can be delayed until the market is more reasonable.

How Can it Be Fixed?

The primary tool used by the government involves reducing the amount of currency in the market, thereby driving up the value of the dollar and reducing inflation’s effect. While easy to say, the implementation aspect is hard. It means increasing the cost of borrowing, making new money more expensive to obtain. Other methods involve reducing the number of income earners generating new value as well. That in turn results in job loss. The list goes on with a singular, common feature – pain. Most solutions for inflation tend to cause more loss, which is why inflation is often feared as a double-damage effect on an economy.

What Can Construction Do as a Solution?

One method of fighting inflation in the construction industry involves finding lower-cost substitutes for supplies and services used. However, this is a bit of a limited option; going too low ends up lowering the quality of the goods or services provided. Since the construction company is ultimately liable for the quality of the entire project delivery, there is a practical floor to how low quality can go before a discounted price isn’t worth taking. After all, the old saying of, “You get what you pay for,” really does apply in construction.

A second method involves financing the inflation as a delay tactic. The thinking here is to let someone else’s money take the hit of inflation through borrowing and, when times are better and currency valuation rises, the financing can be paid off with a lower cost. It is, in essence, gambling that the future will provide a better exchange for the borrower than the cost of the borrowing today. In many cases, this kind of financing out of inflation doesn’t work, and the cost of the construction ends up being far more.

A third method involves maximizing local resources, labor and equipment. While some construction companies insist on bringing all of their resources, cost-sensitive operations focus on finding the resources locally wherever the project happens to be. Again, there is a bit of gambling here; if the resources are not available locally, the company will still have to bring them in to complete the job. At short notice, that could drive the cost higher than if the elements were retained to begin with well in advance.

The Most Sensitive Construction Areas Hit

Among the areas hardest hit, raw material suppliers and equipment fleet managers have been seeing the most noticeable ongoing expense impacts. Fuel for vehicles erodes operating budgets mercilessly. Where construction involves a lot of transport, fuel costs are going to remain a challenge.

Most construction requires raw materials for assembly and end product development. As raw materials go up, the cost of the project increases notably. Materials can reach as much as 60 percent of a construction project’s overall expense, so controlling procurement is essential to protect profit margins. Yet again, the quality issue ties the project’s hands from going too cheap on supplies.

Finally, labor will continue to be a pressure during periods where hiring is difficult. Combined with inflation, deficits in skilled labor and trades can easily drive up salary and wage costs on a project, even with outsourcing and contracting versus direct hires.

Inflation Doesn’t Last Forever, Right?

Much of the expectation in the U.S. is that the current inflation levels will be temporary. However, Japan was a good example where long-lasting economic problems hampered multiple industries for a decade or longer. There’s no rule that says inflation can only last one or two years. Instead, monetary policy tends to be the primary response that makes a difference, reducing supply of currency and increasing economic buying power.

ENTERTAINMENT4 days ago

ENTERTAINMENT4 days agoExploring the Kristen Archives: A Treasure Trove of Erotica and More

ENTERTAINMENT1 day ago

ENTERTAINMENT1 day agoKiss KH: The Streaming Platform Redefining Digital Engagement and Cultural Currents

EDUCATION1 day ago

EDUCATION1 day agoLingrohub Platform: A Complete Student Access Guide

LIFESTYLE4 months ago

LIFESTYLE4 months agoThe Disciplinary Wives Club: Spanking for Love, Not Punishment

TECHNOLOGY24 hours ago

TECHNOLOGY24 hours agoCasibom: The Digital Alchemy Reshaping Systems, Society, and Self

TECHNOLOGY23 hours ago

TECHNOLOGY23 hours agoSecuring Your Online Presence: The Ultimate Guide to Buying an SSL Certificate

LIFESTYLE23 hours ago

LIFESTYLE23 hours agoTips for Prolonging the Lifespan of Truck Roll-Up Door Rollers

TECHNOLOGY4 months ago

TECHNOLOGY4 months agoBlog Arcy Art: Where Architecture Meets Art