AUTOMOTIVE

Installation Guide for FPV Drone Motors: Tips and Procedures

1. Introduction

FPV (First Person View) drones are beloved by drone enthusiasts for their agility, speed, and ability to offer an engaging perspective during flight. Installing motors on an FPV drone is a crucial phase to ensure optimal performance and safety during flight. In this guide, we will explore the basic details of installing drone motor on FPV drones, including ESC/motor compatibility, motor mounting, cable routing, measuring cables to fit desired lengths, and troubleshooting common issues.

2. ESC/Motor Compatibility

Before starting the motor installation process, it’s essential to ensure that the Electronic Speed Controllers (ESCs) are compatible with the motors you intend to use. ESCs regulate the speed and direction of motor rotation and must be capable of handling the current required for motor operation. Therefore, it’s necessary to ensure that the ESCs support the current and voltage required by the motors, in addition to being compatible with the drone’s flight controller firmware.

3. Motor Mounting

3.1. Motor Attachment

Use appropriate screws and nuts to secure the motors to the drone frame. Ensure that the motors are securely fastened to prevent unwanted movements during flight and that the screws do not touch or are close to the stators (this could cause motor overheating issues).

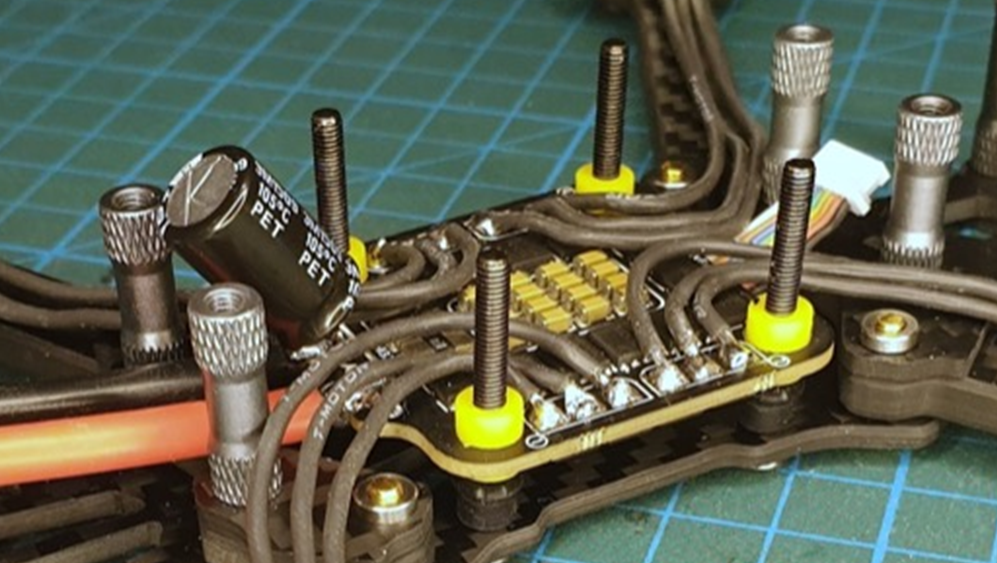

3.2. Use of Insulating Gaskets and Racewiring

To reduce vibrations and protect electronic components, it is advisable to use insulating gaskets between the motors and the drone frame. Racewiring can also be used if the motor cables are too short or if you want to facilitate motor replacement in the future.

3.3. Cable Routing

3.3.1. Planning Cable Routing

Before connecting the motor cables to the ESCs, plan the cable routing to ensure a neat and safe installation. Avoid cable crossings or tangles that could interfere with motor movements or other drone components. It’s also possible to route the cables internally between the Flight Controller (FC) and ESC (in the case of a stack), which helps to have a cleaner build visually and allows leaving the motor cables longer; however, leaving internal cables may cause vibrations.

3.3.2. Use of Cable Protections and Fastening

To prevent leaving the cables loose, it is necessary to protect and secure them on the arm; for this purpose, there are several solutions: hard plastic tubing (not recommended because they break at the first crash), electrical tape, zip ties, cloth tape (the best in experience), etc.

3.4. Measuring Cables

3.4.1. Determine Cable Length Measure

The distance between the motors and ESCs to determine the length of cables needed. It is advisable to leave an additional margin to allow for movements and adjustments during installation. Pay attention to the frame type; the length of cables may vary depending on the arm.

3.4.2. Cable Cutting Once

The desired cable length is determined, carefully cut them using pliers or scissors designed for electrical cables, strip the ends, and pre-solder them.

3.4.3. Cable Soldering Connect

The motor cables to the ESCs using the appropriate soldering technique. Ensure that the connections are solid, secure, and that the solder does not contact adjacent pads or other ESC components to avoid false contacts, disconnections during flight, or short circuits.

By carefully following these steps and considering component compatibility, mounting motors on an FPV drone can be a rewarding process that improves the performance and stability of your drone during flight. Always remember to perform a thorough pre-flight check to ensure that all components are properly installed and functioning as expected; now let’s move on to motor configuration.

4. Motor Configuration

Configuring motors on an FPV drone is a crucial step to ensure optimal performance and a good flying experience. Using a flight configurator, such as Betaflight, Cleanflight, or Kiss, you can customize various parameters to tailor your drone’s behavior to your flying preferences. Below are the various steps to configure motors with our flight configurator.

4.1. Connection and Preparation

Before starting, make sure your drone is connected to the computer via a USB cable and that the flight configurator is open and correctly configured to communicate with the drone. Also, ensure that the propellers have been removed, and the drone’s battery is disconnected to avoid accidents.

4.2. Access to the Motor tab

Once connected, open the flight configurator and go to the section dedicated to motors. This section will allow you to adjust the parameters of individual motors according to your needs; this is where we will begin our configuration.

4.3. Checking Motor Order and Rotation Direction

Ensure that your drone’s motors are connected to the correct pins on your flight control board. Otherwise, the motors may spin in the wrong direction or not respond correctly to inputs. Check that the motor order is correct or change it through the configurator. Once it is confirmed that the order is correct, check the rotation direction (prop-in/prop-out) and that all motors respect the correct direction.

4.4. Motor Settings

Now is the time to adjust the motor settings. These settings include maximum motor speed, communication protocol, and other advanced options. Make sure you have your motor and ESC manuals handy to correctly configure the settings. For example, on a blheli_s ESC, it is recommended to download the Bluejay firmware.

4.5. Motor Testing

After setting the motor parameters, it is advisable to perform a test to ensure that all motors spin in the correct direction and respond uniformly to throttle inputs (WARNING: remove the propellers as previously stated). You can do this using the flight configurator, which will allow you to individually activate each motor.

4.6. Fine Tuning and Flight Test

Once the motor configuration is complete, it is advisable to perform some flight tests to verify that the drone behaves as desired. If necessary, further adjustments can be made to the motor parameters to improve performance or adapt the drone’s behavior to your flying preferences through PID tuning.

4.7. Safety Considerations

Before taking off, always make sure to perform a thorough check of your drone to ensure that all components are securely fastened and that there are no obvious damages. Always respect local regulations and fly in designated areas to avoid accidents and hazards to yourself and others.

We have seen how to mount and solder the motors, how to configure them; now let’s see the most common issues we may encounter.

5. Resolving Common Issues During FPV Drone Motor Installation

As we have seen, installing motors on an FPV drone is a crucial part of building a quadcopter. However, some issues may arise during this process. Let’s see what the most common challenges are and how to address them:

5.1. Vibrations and Abnormal Oscillations

- Possible Causes: Vibrations can be caused by unbalanced motors, damaged propellers, or incorrect motor mounting on the frame.

- Solutions: Balance the motors using a prop balancer. Check that the propellers are not damaged and securely mount the motors on the frame, using insulating gaskets if necessary.

5.2. Excessive Heat on Motors

- Possible Causes: Excessive current through the motors, poor airflow, screws too long and therefore too close to the stator, incorrect PID settings, incorrect ESC firmware, can cause overheating.

- Solutions: Check that the ESCs are calibrated correctly and that the current supplied to the motors is adequate. Ensure that the airflow around the motors is sufficient , avoiding obstructions in the drone frame, recheck the screws, and finally, if the problem persists, review the PID settings.

5.3. Cable Connection Problems

- Possible Causes: Damaged cables, loose connections, or faulty solder joints can cause connection problems.

- Solutions: Inspect the cables carefully for any damage. Ensure that the connections are securely connected and that the solder joints are of good quality; also recheck the cable bends in case they have been forced and may have broken internally.

5.4. Motors Not Starting or Not Responding Correctly

- Possible Causes: Incorrect ESC configuration, power issues, motor or ESC damage, incorrect ESC-motor connections and/or ESC/FC connections can cause motor malfunction.

- Solutions: Check the ESC configuration and reprogram them if necessary. Check that the power supply is correct and that there are no interruptions in the electrical circuits. Inspect the motors for any physical damage. Recheck the connector that connects FC to ESC (in some stacks, it is necessary to pay attention to which connector is inserted into the ESC and which connector is inserted into the FC, having a different min order).

5.5. Strange Noises During Motor Operation

- Possible Causes: Some abnormal noises may indicate mechanical damage to the motors; in other cases, there may be abnormal noises due to incorrect PID settings, misaligned bells, dirty motors, or incorrect configuration.

- Solutions: Visually inspect the motors for any signs of damage or wear. Recheck the PID settings, motor, and ESC configuration, give the motors a clean.

5.6. ESC/Motor Compatibility Issues

- Possible Causes: ESCs may not be suitable for the motors in use or may not be compatible with the flight controller firmware.

- Solutions: Check the compatibility of ESCs and motors using technical specifications and manufacturer recommendations. Update the flight controller firmware if necessary.

Addressing these issues requires patience and attention to detail. With proper diagnosis and the right solutions, most problems that may arise during the installation of motors on an FPV drone can be successfully resolved. If problems persist, consult online resources (social media communities can also be a great source of help) or seek assistance from industry experts for additional support.

AUTOMOTIVE

Why F&I Training is Important For Automotive Dealerships In The USA

In the realm of automotive sales, the Finance and Insurance (F&I) department serves as a crucial nexus between customers and dealerships. It’s the bridge where financial transactions are sealed, and customer satisfaction is solidified. In today’s competitive market, where customer expectations are higher than ever, the significance of well-trained F&I professionals cannot be overstated. Let’s delve into why F&I training is not just beneficial but essential for automotive dealerships aiming to thrive in the modern landscape.

Finance Manager Training, accredited by the Bureau of Proprietary F&I Training School Supervision, specializes in educating future F&I Managers for automotive, RV, and powersports dealerships.

Expertise Breeds Confidence

In the intricate world of automotive financing and insurance, knowledge is power. F&I professionals equipped with comprehensive training exude confidence and authority. They can effortlessly navigate through complex financing options, explain intricate insurance policies, and address customer queries with clarity. This expertise doesn’t just inspire trust; it instills confidence in customers, assuring them that they’re making well-informed decisions. Consequently, confident customers are more likely to proceed with purchases, ultimately driving sales and enhancing dealership profitability.

Compliance and Risk Mitigation

The regulatory landscape governing automotive financing and insurance is constantly evolving. From consumer protection laws to compliance requirements imposed by lending institutions, staying abreast of these regulations is paramount. F&I training programs not only educate professionals about existing laws but also provide insights into emerging trends and regulatory changes. By ensuring adherence to compliance standards, F&I training mitigates legal risks for dealerships, shielding them from costly penalties and litigations that could tarnish their reputation and financial standing.

Upselling and Maximizing Revenue

An adept F&I professional isn’t just a facilitator of transactions; they are also skilled at uncovering opportunities to enhance revenue. Through upselling supplementary products such as extended warranties, maintenance plans, or gap insurance, F&I managers can significantly augment dealership profits. However, the art of upselling requires finesse and persuasion, traits honed through targeted training programs. By equipping F&I staff with upselling techniques and product knowledge, dealerships can capitalize on revenue-generating opportunities without compromising customer satisfaction.

Enhancing Customer Experience

In an era dominated by customer-centricity, delivering exceptional experiences is imperative for sustaining competitive advantage. The F&I process, often perceived as a bottleneck, presents a prime opportunity to delight customers. Well-trained F&I professionals understand the significance of a seamless and personalized experience. By cultivating rapport, actively listening to customer needs, and offering tailored solutions, they transform mundane transactions into memorable interactions. These positive experiences not only foster customer loyalty but also generate favorable word-of-mouth referrals, amplifying dealership reputation and goodwill.

Continuous Improvement and Adaptability

The automotive industry is dynamic, characterized by evolving consumer preferences, technological advancements, and market disruptions. In this landscape of constant flux, static knowledge quickly becomes obsolete. F&I training isn’t a one-time event but a continuous journey of learning and adaptation. Dealerships that prioritize ongoing training initiatives empower their F&I teams to stay ahead of the curve. Whether it’s mastering new digital tools, understanding emerging financing models, or embracing innovative sales strategies, continuous training fosters agility and resilience, enabling dealerships to thrive amidst change.

In conclusion, F&I training isn’t merely an investment; it’s a strategic imperative for automotive dealerships committed to success. By equipping F&I professionals with the requisite skills, knowledge, and confidence, dealerships elevate their proficiency, enhance customer satisfaction, and drive profitability. In an industry where margins are razor-thin and competition is fierce, the difference between mediocrity and excellence often lies in the caliber of F&I training. As automotive retail continues to evolve, those who embrace the transformative power of education will emerge as industry leaders, charting a course towards sustained growth and prosperity.

AUTOMOTIVE

BMVX4: The Innovation Driving Accuracy and Automation

Introduction to BMVX4

In a world where precision and efficiency reign supreme, the BMVX4 emerges as a game changer. This innovative technology is not just another tool; it’s a leap forward in automation that promises to enhance accuracy across various sectors. Imagine streamlined processes, reduced errors, and an overall boost in productivity all thanks to this remarkable advancement. As industries continue to evolve and embrace digital transformation, understanding how BMVX4 works and its potential impact becomes essential. Buckle up as we explore the ins and outs of this groundbreaking innovation driving the future of automation!

What is BMVX4 and How Does it Work?

BMVX4 is a cutting-edge technology designed to enhance precision and automate processes across various sectors. At its core, BMVX4 utilizes advanced algorithms and real-time data analysis to optimize performance.

This innovative system integrates seamlessly with existing infrastructure. It collects vast amounts of information from multiple sources, ensuring every decision is based on accurate data.

The mechanics behind BMVX4 involve machine learning and artificial intelligence. These components enable the system to adapt over time, improving efficiency without human intervention.

Users can customize BMVX4 according to their specific needs. This flexibility allows companies to apply it in manufacturing, logistics, healthcare, and more.

With user-friendly interfaces and robust support systems, organizations find it easy to implement BMVX4 into their workflows. The result? A streamlined operation that minimizes errors while maximizing productivity.

Benefits of Using BMVX4 in Different Industries

BMVX4 offers transformative benefits across various industries. In manufacturing, its precision enhances production lines, minimizing errors and reducing waste. This leads to significant cost savings.

In healthcare, BMVX4 streamlines operations through accurate data management. It aids in patient record keeping and improves diagnostic accuracy, ensuring better outcomes for patients.

The finance sector also gains from BMVX4’s automation capabilities. With its ability to analyze vast datasets quickly, it helps institutions make informed decisions while mitigating risks.

Retail businesses benefit greatly too. By implementing BMVX4 technology, they can personalize customer experiences based on real-time analytics and inventory tracking.

Logistics companies leverage BMVX4 for efficient route planning and delivery scheduling. This ensures timely shipments while optimizing fuel costs and resources used in the process.

Case Studies: Real-Life Examples of BMVX4 in Action

BMVX4 has made waves in various sectors, showcasing its versatility and effectiveness. In the manufacturing industry, a leading automotive company integrated BMVX4 to streamline their assembly line processes. The result was a remarkable reduction in errors and an increase in production speed.

Another compelling example comes from healthcare. A hospital utilized BMVX4 for patient data management. This innovation enhanced accuracy in record-keeping, allowing medical staff to focus more on patient care rather than administrative tasks.

In retail, one major chain employed BMVX4 for inventory tracking. By automating stock management, they minimized waste and optimized supply chains significantly.

These case studies highlight how BMVX4 is not just theoretical; it delivers practical results that transform operations across diverse fields. Each instance serves as evidence of its potential to redefine accuracy and efficiency.

The Future of Automation with BMVX4

The future of automation is bright, especially with BMVX4 at the forefront. This technology promises to redefine operational efficiency across various sectors.

As industries embrace smart solutions, BMVX4 stands out by integrating advanced algorithms that enhance decision-making. The ability to process vast amounts of data in real-time sets it apart from traditional systems.

Moreover, its adaptability makes it suitable for diverse applications—from healthcare diagnostics to manufacturing precision. Businesses can expect improved accuracy and reduced errors as they implement this innovative tool.

Collaboration between humans and machines will evolve significantly too. With BMVX4 handling routine tasks, professionals can focus on strategic initiatives and creative problem-solving.

As we look ahead, continuous advancements in artificial intelligence will further amplify the capabilities of BMVX4. Companies investing in this technology are likely to lead their industries into a new era of productivity and innovation.

Challenges and Limitations of BMVX4

While BMVX4’s offers remarkable advancements, it is not without its challenges. One significant limitation is the initial cost of implementation. Businesses may find the investment daunting, especially small to medium enterprises.

Integration with existing systems can also pose difficulties. Many organizations rely on legacy software that may not be compatible with BMVX4’s advanced features. This can lead to increased downtime and additional costs during transition phases.

There are also growing worries about protecting data and maintaining security. As BMVX4’s automates processes using large volumes of sensitive information, safeguarding this data becomes critical. Any security lapse could seriously damage confidence in the technology.

Furthermore, users must invest time in training staff to fully utilize BMVX4’s capabilities. Without proper training, companies risk underutilizing this powerful tool or facing operational hiccups due to misunderstandings about its functions.

Conclusion: The Impact of BMVX4 on Accuracy and Automation

The BMVX4’s stands out as a transformative force in the realms of accuracy and automation. Its innovative technology redefines how industries operate, allowing for heightened precision that was previously unattainable. Businesses leveraging BMVX4’s see significant improvements in efficiency, enabling them to focus on core tasks while reducing human error.

As more sectors embrace this cutting-edge solution, it’s evident that the future of automation is bright. The potential applications are vast, from manufacturing to healthcare and beyond. Each industry can tailor BMVX4’s capabilities to meet their unique needs.

Despite its advantages, challenges remain. Integration into existing systems may pose difficulties, and understanding the full scope of its functionalities requires training and adaptation. Nevertheless, these hurdles do not overshadow the benefits offered by BMVX4’s.

As organizations continue to invest in technologies like BMVX4’s, we can anticipate a significant shift towards greater accuracy and streamlined processes across various fields. This innovation promises to pave the way for enhanced productivity and competitiveness in an increasingly automated world.

AUTOMOTIVE

Electric Outboard Motors: The Clean, Quiet, and Smarter Future of Boating

Boating enthusiasts around the world are witnessing a major shift in marine propulsion, and at the center of this transformation are electric outboard motors. These motors have rapidly gained popularity due to their efficiency, environmental benefits, low maintenance, and advanced performance capabilities. As technology continues to push boundaries, electric propulsion is not just an alternative to gas-powered engines—it is becoming the preferred choice for a new era of clean and sustainable boating.

Today, we explore everything you need to know about electric boating, why so many boaters are switching, and where to find premium electric outboard boat motors from trusted brands. This guide is designed to help you make a confident and informed decision while enhancing your boating experience for years to come.

What Are Electric Outboard Motors?

Electric outboard motors are propulsion systems powered by battery-stored electricity rather than gasoline. They use high-efficiency electric motors to drive a propeller, delivering smooth, silent, and eco-friendly performance on the water. Because they eliminate fuel combustion, they avoid the fumes, noise, and pollution common with traditional motors.

These motors have evolved significantly over the past decade, becoming more powerful, compact, and technologically advanced. Today’s designs offer:

- High torque output

- Long battery life

- Durable marine-grade construction

- Smart digital controls

- Fast charging capabilities

This combination makes them ideal for fishing boats, inflatable dinghies, pontoons, sailboats, small crafts, and more.

Why Electric Outboard Motors Are the Future of Boating

1. Zero Emissions and Eco-Friendly Operation

More lakes, rivers, and protected marine zones are regulating or banning combustion engines due to pollution. Electric outboard motors help boaters meet environmental standards without compromising performance. With zero emissions, they protect water quality, marine animals, and air purity.

2. Quiet and Smooth Ride

Noise is one of the biggest drawbacks of gas-powered engines. Electric motors eliminate engine roar—providing whisper-quiet performance. This is perfect for fishing, wildlife observation, relaxing cruises, and early morning rides.

3. Low Maintenance and Long Lifespan

Electric motors contain fewer moving parts than combustion engines. That means:

- No oil changes

- No spark plugs

- No carburetor issues

- No fuel filters

- No exhaust leaks

This results in significantly lower maintenance costs and fewer mechanical problems over time.

4. Lower Operating Costs

Electricity is far cheaper than gasoline. Combined with low maintenance needs, electric outboard boat motors offer exceptional long-term savings.

5. Instant Torque for Strong Acceleration

Electric motors deliver power instantly. Unlike gasoline engines that build power gradually, electric propulsion offers immediate thrust—ideal for quick takeoff, steering control, and smooth maneuvering.

How to Choose the Right Electric Outboard Motor

If you are planning to invest in electric outboard motors, consider the following factors to ensure optimal performance:

Battery Type and Capacity

Lithium-ion batteries are the industry standard thanks to their:

- Lightweight build

- Faster charging

- Longer lifespan

- Higher energy density

Choose a battery with enough capacity (measured in kWh or Ah) to support your typical boating duration.

Motor Power (kW / HP Equivalent)

Electric motors are rated in kilowatts, but many manufacturers provide horsepower equivalents. Match the motor power to your boat’s size, weight, and intended use.

Boat Size and Load

Larger boats require more thrust. Always select a motor designed to handle your typical passenger load and equipment weight.

Range and Runtime

Runtime depends on battery size and speed. For long journeys, consider portable backup batteries or high-capacity lithium packs.

Charging Options

Many motors now include:

- Fast chargers

- Solar charging compatibility

- Regenerative systems (on some hybrid models)

Choose a charging setup that aligns with your lifestyle and boating frequency.

Top Choice for High-Quality Electric Outboard Boat Motors

For boaters who want premium performance, durability, and smart engineering, Scott Electric Outboard is one of the most trusted names in the industry. Their lineup offers industry-leading efficiency and reliable long-term performance.

Whether you need a compact motor for a tender or a high-powered system for a larger craft, Scott Electric Outboard offers top-rated solutions backed by expert support.

Benefits of Choosing Scott Electric Outboard Motors

Scott Electric Outboard has earned a strong reputation for delivering modern, reliable, high-performance motors. Here’s why boaters trust them:

1. Superior Efficiency

Their motors are designed to maximize power output while extending runtime—allowing more hours on the water per charge.

2. Long-Lasting Marine-Grade Construction

Built with corrosion-resistant materials, these motors perform reliably in both fresh and saltwater conditions.

3. Smart Digital Features

Many models include:

- LED battery indicators

- Smart throttle systems

- GPS-integrated control

- Safety features like low-battery alerts

4. Eco-Friendly and Quiet

These motors are perfect for fishing, island hopping, wildlife tours, and recreational boating.

5. Trusted Mercury Electric Options

Their Mercury electric outboard lineup offers cutting-edge innovation with unmatched marine engineering quality.

Electric Outboard Motors vs. Gasoline Motors: Which Is Better?

Below is a comparison to help you evaluate the best choice for your needs:

| Feature | Electric Motors | Gas Motors |

| Noise Level | Ultra-quiet | Loud |

| Emissions | Zero | High |

| Maintenance | Very low | High |

| Operating Cost | Very low | Expensive |

| Lifespan | Long | Moderate |

| Eco-Friendly | Yes | No |

| Starting System | Instant start | Manual/electric start |

| Vibration | Minimal | High |

For most recreational users, electric motors offer superior advantages in comfort, reliability, and sustainability.

Applications of Electric Outboard Boat Motors

Electric propulsion is suitable for a wide variety of boating activities:

- Fishing trips

- Family cruising

- Dinghies & tenders

- Kayaks and inflatable boats

- Pontoons

- Sailboats (as auxiliary motors)

- Resorts & eco-tourism operations

- Rental fleets

- Wildlife and photography tours

Their silent performance and eco-friendly design make them ideal for peaceful and protected waters.

Final Thoughts: Why Now Is the Best Time to Go Electric

With rising fuel prices, tighter environmental regulations, and rapid advancements in battery technology, investing in electric outboard motors is one of the smartest boating decisions you can make today. These motors offer unmatched efficiency, quiet performance, and long-term savings—all while helping protect the environment.

Explore more articles built to elevate your mindset and unlock new possibilities.

HOME IMPROVEMENT12 months ago

HOME IMPROVEMENT12 months agoThe Do’s and Don’ts of Renting Rubbish Bins for Your Next Renovation

BUSINESS1 year ago

BUSINESS1 year agoExploring the Benefits of Commercial Printing

BUSINESS12 months ago

BUSINESS12 months agoBrand Visibility with Imprint Now and Custom Poly Mailers

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoDizipal 608: The Tech Revolution Redefined

HEALTH8 months ago

HEALTH8 months agoThe Surprising Benefits of Weight Loss Peptides You Need to Know

HEALTH8 months ago

HEALTH8 months agoYour Guide to Shedding Pounds in the Digital Age

HOME IMPROVEMENT8 months ago

HOME IMPROVEMENT8 months agoGet Your Grout to Gleam With These Easy-To-Follow Tips

HEALTH11 months ago

HEALTH11 months agoHappy Hippo Kratom Reviews: Read Before You Buy!