GENERAL

What to Look for When Buying a Bolt Carrier Group?

Law enforcement agencies and armed forces in the United States and other countries employ AR-15s because they are among the most dependable and capable weapons available. While every component of the rifle plays a role in its dependability and efficiency, the bolt carrier group (BCG) is one of the most crucial.

Bolt carrier group alternatives abound on the market for AR-15 builders, each with a unique set of features and specifications. When discussing BCGs, a lot of words are used, such as “M16 BCG,” “full auto,” and staked gas keys.

The AR15 Bolt Carrier Group (BCG) is considered to be the heart of your AR-15 platform. It is liable for biking ammunition and ejecting spent casings. When you are up to selecting the proper BCG is essential for reliable operation, smooth functioning, and average firearm overall performance. This articles emphasizes the key concerns to help you select the top-rated BCG for your desires.

What Makes a Good BCG and Why Does It Matter?

A great BCG contributes to appreciably factors and reliability – overall performance of your AR-15. Here are the reasons:

Reliability: A nicely-made BCG ensures clean biking and right cartridge extraction/ejection. Besides, it also helps minimizing malfunctions and stoppages.

Although it is paramount for secure and reliable operations, specifically when it comes to deal with critical conditions.

Durability: BCGs enjoy great pressure during firing. It is better to choose a BCG made from sturdy substances and coatings.

This strategy guarantees that it could face up to extended use without overall performance degradation.

Performance: Certain BCG functions are known to enhance performance and ultimate reliability.

Nickel Boron coatings, for instance, lessen friction, leading to smoother cycling and potentially quicker firing fees. One of its characteristics is lightweight BCGs. And, this can enhance handling characteristics.

How Many Types of BCGs Are There? Types/Profiles

BCGs are available diverse configurations, every acceptable for unique applications:

Mil-Spec BCG: The enterprise trendy, Mil-Spec BCGs are constituted of chrome moly steel and phosphate. These also contribute to making it corrosion resistance.

They offer a balance of affordability and reliable performance. These properties also make them a popular preference for fashionable-purpose AR-15 builds.

Nickel Boron (NiB) BCG: With a soft nickel boron coating, these BCGs provide exceptional lubricity. This makes for better cycling, reduces wear and is easier to clean.

NiB BCGs are a popular upgrade for increased performance and corrosion resistance.

Nitride BCG: This BCG involves a hardening process that improves wear and corrosion resistance. Hardening process also provides a smooth surface for improved performance.

Nitride-containing BCGs strike a good balance between price and performance improvement.

Lightweight BCGs: These CBGs are made from materials such as titanium or scandium. The same BCGs prioritize weight loss. This can be useful for competition shooting or where improved control is desired.

However, lightweight BCGs may require specific tuning (e.g., adjustable gas block) for reliable operation.

Fully-Auto BCG: Originally designed for the M16 rifle.

These BCGs can be used on semi-auto AR-15s. In automatic systems, they are often heavier to provide reliable cycling.

While not necessary for a civilian AR-15, some users may prefer a more capable performance due to the increased weight.

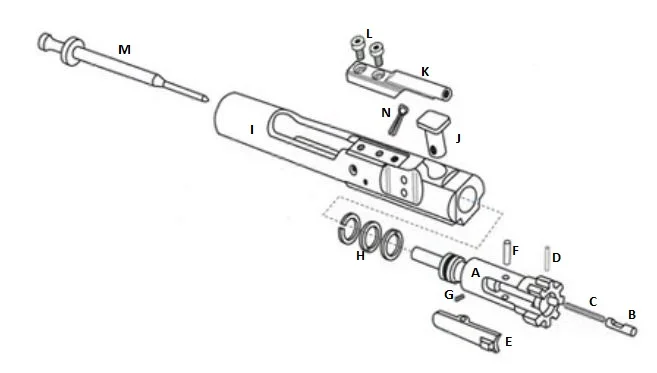

Contents of BCG

The primary ingredients of BCG greatly influence its activity and durability. Here are some of the most commonly used:

Chrome Moly Steel (4150): Industry standard for Mil-Spec BCGs, chrome moly steel provides excellent strength balance, affordability and mechanical performance

Stainless Steel: Provides corrosion resistance but is heavier and more expensive than chrome moly steel.

Tool steel: It offers superior wear resistance but is commonly used for conventional BCG parts due to its high cost.

Titanium: A valuable lightweight choice for a high strength-to-weight ratio, but requires adequate lubrication to prevent galling.

Scandium: Lighter than titanium, offers maximum weight reduction but at a higher price.

Coverage for BCG

A variety of coatings beyond the base material can enhance the performance and lifetime of BCG:

Phosphate coating (parkerizing): A common, cost-effective coating that provides initial corrosion resistance to mil-spec BCG.

Nickel Boron (NiB): Provides exceptional lubrication for smoother, less corrosive and easier to clean bikes.

Nitriding: Increases BCG surface toughness, corrosion and corrosion resistance and makes it slicker for better performance.

Chrome: Provides corrosion resistance and excellent flexibility, but is generally more expensive than other options.

Best Bolt Carrier Group Conclusion and Recommendations

The best BCG for your AR-15 depends on your specific needs and budget. Here’s a breakdown to guide you through the decision-making process:

Budget-conscious design: Mill-spec phosphate-coated BCG is a reliable and inexpensive option for all-purpose use.

Improved performance: Consider nickelboron or nitride BCG for better cycling, improved corrosion resistance, and potential wear reduction.

Competition or weight reduction: Lightweight BCGs made of titanium or scandium may be advantageous, but the gas system may need to be fine-tuned for reliability.

Remember to consider factors such as gas system compatibility, shooting style (loud stuff or tight spots), and brand reputation when making your final choice. By carefully researching these products and tailoring your selection to your specific needs, you can ensure that you choose the perfect bolt carrier set that will ensure maximum performance and longevity.

Other factors to consider

Here are some other things to keep in mind when choosing a BCG.

MPI & HP testing: Magnetic particle inspection (MPI) and high-pressure testing (HP) testing are quality control measures that ensure that the BCG is free from defects and can withstand high pressures during operation. Look for BCGs that have designed these tests for those with greater peace of mind.

Extractor spring and O-ring: These components directly influence evacuation and clearance reliability. Ensure that the BCG you have selected uses high quality extractor springs and O-rings for proper operation. Some manufacturers offer alternatives to these products.

Brand Reputation: When choosing a BCG manufacturer, consider their reputation for quality and customer service. Explore online reviews and forums to gain insight from other AR-15 enthusiasts.

Maintenance

Regular maintenance is essential to ensure the effectiveness and longevity of your BCG. Regardless of coating or coating, proper cleaning and lubrication is essential. Here are some basic maintenance tips.

Cleaning: After shooting, disassemble your BCG and thoroughly use an AR-specific cleaning solvent and a popular lubricant. Be careful with bolt lugs, carrier keys, and gas keys for any carbon assembly.

Lubricant: Once clean, apply a thin layer of AR-specific lubricant to all spray parts of the BCG. Check your manufacturer’s recommendations for specific lube areas and types.

Conclusion

Choosing the right bolt carrier set is an important step in building or maintaining a reliable and efficient AR-15 platform. By understanding the types, materials, coatings, and other considerations you can make an informed decision tailored to your specific needs and budget Remember, a well maintained BCG is an investment ensuring years of reliable service from your AR-15.

GENERAL

The Charm of Singing Waiters for Memorable Wedding Celebrations

Singing waiters for weddings infuse your special day with an unparalleled charm, elevating the ambiance to pure magic. These exceptional performers seamlessly blend into the catering staff, surprising and delighting guests with their extraordinary vocal talents. Let’s delve into the enchanting world of singing waiters and discover why they’re the ultimate addition to your wedding celebration.

Experience the Elegance of Live Entertainment

Imagine the awe on your guests’ faces as they are serenaded by professional singers disguised as waiters. This unique form of live entertainment adds a touch of sophistication and class to your wedding festivities. From romantic ballads to upbeat tunes, singing waiters effortlessly set the mood, creating memorable moments that will be cherished for years to come.

Create Memorable Moments with Surprise Performances

One of the most delightful aspects of singing waiters is the element of surprise they bring to your event. Guests are taken aback when their servers suddenly burst into song, turning an ordinary dining experience into an extraordinary performance. Whether it’s during cocktail hour, dinner service, or dessert, these talented singers know exactly when to captivate your audience with their stellar vocals.

Personalize Your Playlist for a Bespoke Experience

With singing waiters, you have the flexibility to customize your musical repertoire to suit your taste and preferences. Whether you’re a fan of classic love songs, contemporary hits, or Broadway show tunes, you can curate a playlist that reflects your unique style as a couple. From the first dance to the grand finale, every song is carefully selected to enhance the romance and joy of your special day.

Enhance the Atmosphere with Professional Talent

Unlike traditional wedding entertainment, singing waiters offer a dynamic and interactive experience that engages guests on a deeper level. With their professional training and stage presence, these performers know how to command attention and create a vibrant atmosphere that keeps everyone entertained. Whether they’re serenading the newlyweds or encouraging guests to join in on the fun, singings waiters bring an energy and excitement that is simply irresistible.

Leave a Lasting Impression on Your Guests

Your wedding day is a reflection of your love story, and every detail should be thoughtfully curated to leave a lasting impression on your guests. By incorporating singing waiters into your celebration, you’re not only adding a unique and memorable touch, but you’re also creating an experience that will be talked about long after the last dance. From the heartfelt performances to the joyous reactions of your loved ones, singings waiters ensure that your wedding is truly unforgettable.

Conclusion

Singing waiters for weddings offer a magical blend of live entertainment, surprise performances, and personalized charm that elevate your special day to new heights. With their exceptional talent and dynamic presence, these performers create unforgettable moments that will be cherished by you and your guests for a lifetime. So why settle for the ordinary when you can experience the extraordinary? Make your wedding truly unforgettable with the enchanting allure of singings waiters.

FAQs

What exactly are singing waiters?

Singings waiters are professional performers who disguise themselves as waitstaff at weddings and other events. They seamlessly blend into the catering team and surprise guests with unexpected vocal performances throughout the event.

How do singing waiters enhance the wedding experience?

Singings waiters add a unique and memorable element to weddings by providing live entertainment that is both surprising and delightful. Their performances elevate the atmosphere, creating magical moments that guests will always remember.

Can I choose the songs for the singing waiters to perform?

Yes, one of the advantages of hiring singings waiters is the ability to personalize the playlist to suit your preferences. Whether you prefer romantic ballads, upbeat tunes, or a mix of genres, you can work with the performers to create a bespoke musical experience for your wedding.

When and where do singing waiters typically perform during the wedding?

Singing waiters can perform at various points throughout the wedding, including during cocktail hour, dinner service, or dessert. Their performances are strategically timed to surprise and entertain guests at key moments during the celebration.

How do I ensure a seamless integration of singing waiters into my wedding plans?

To ensure a seamless integration of singings waiters into your wedding plans, it’s essential to communicate with your event planner or catering coordinator. Provide them with the necessary information about the performers and discuss any specific requests or preferences you may have regarding their performance schedule and repertoire. This will help ensure that the singings waiters complement your wedding vision and enhance the overall guest experience.

GENERAL

Covered Comfort: Crafting Custom Awning Manufacturing for Your Outdoor Oasis

Introduction to Awning Manufacturing

Awning manufacturer is a meticulous process that involves crafting protective coverings for windows, doors, patios, and outdoor spaces. These structures not only offer shade and protection from the elements but also enhance the aesthetic appeal of buildings and outdoor areas. In this article, we’ll delve into the world of awning manufacturing, exploring the various types, materials used, the manufacturing process, benefits, challenges, and future trends.

Types of Awnings

Retractable Awnings

Retractable awnings are versatile structures that can be extended or retracted as needed. They are ideal for both residential and commercial settings, offering flexibility and convenience.

Fixed Awnings

Fixed awnings are permanently attached to a building or structure, providing continuous protection from sun, rain, and other weather conditions. They are popular for their durability and stability.

Freestanding Awnings

Freestanding awnings are standalone structures that can be placed anywhere in outdoor spaces such as gardens, patios, or poolside areas. They offer shade and shelter without the need for attachment to a building.

Materials Used in Awning Manufacturing

Awnings are crafted from a variety of materials, each offering unique properties and benefits.

Fabric

Fabric awnings are commonly made from materials such as canvas, acrylic, or polyester. These fabrics are durable, weather-resistant, and come in a wide range of colors and patterns to suit different preferences.

Metal

Metal awnings, typically made from aluminum or steel, are known for their strength and longevity. They are highly resistant to corrosion and can withstand harsh weather conditions.

Plastic

Plastic awnings, often constructed from materials like PVC or polycarbonate, are lightweight and easy to maintain. They are also available in various styles and colors, making them a popular choice for modern designs.

The Process of Awning Manufacturing

The manufacturing process of awnings involves several stages, from designing to installation.

Designing

The first step in awning manufacturing is designing. This involves creating detailed plans and specifications based on the client’s requirements and the intended use of the awning.

Fabrication

Once the design is finalized, the fabrication process begins. This includes cutting, sewing, and assembling the various components of the awning, such as the frame, fabric, and hardware.

Installation

The final stage is the installation of the awning. This requires careful positioning and mounting to ensure proper functionality and stability.

Key Considerations in Awning Manufacturing

When manufacturing awnings, several factors need to be taken into account to ensure quality and customer satisfaction.

Durability

Durability is crucial for awnings to withstand exposure to sun, wind, rain, and other environmental factors. High-quality materials and construction techniques are essential for long-lasting performance.

Aesthetic Appeal

Awnings play a significant role in enhancing the visual appeal of buildings and outdoor spaces. Choosing the right design, fabric, and color can greatly contribute to the overall aesthetic of a property.

Functionality

Functionality is another important consideration in awning manufacturing. Awnings should be easy to operate, provide adequate shade and protection, and complement the architectural style of the building.

Benefits of Choosing a Reputable Awning Manufacturer

Opting for a reputable awning manufacturer offers several advantages, including:

- High-quality craftsmanship

- Customization options

- Professional installation services

- Warranty coverage and after-sales support

Factors to Consider When Choosing an Awning Manufacturer

When selecting an awning manufacturer, it’s essential to consider the following factors:

Experience

Choose a manufacturer with extensive experience in the industry and a proven track record of delivering quality products and services.

Reputation

Research the manufacturer’s reputation by reading customer reviews, testimonials, and checking their credentials and certifications.

Customer Service

Excellent customer service is crucial for a positive experience. Look for manufacturers who prioritize customer satisfaction and offer responsive support throughout the purchasing process.

Trends in Awning Manufacturing

As technology and design trends evolve, so do awning manufacturing techniques. Some emerging trends in the industry include:

- Motorized awnings with remote control functionality

- Smart awnings equipped with sensors for automatic operation

- Sustainable materials and eco-friendly designs

Sustainability in Awning Manufacturing

With growing concerns about environmental conservation, sustainability has become a key focus in awning manufacturing.

Eco-friendly Materials

Many manufacturers are transitioning to eco-friendly materials such as recycled fabrics, sustainable woods, and low-impact production processes to reduce their environmental footprint.

Energy Efficiency

Energy-efficient awnings, designed to minimize heat gain and reduce cooling costs, are gaining popularity among environmentally conscious consumers.

Challenges Faced by Awning Manufacturers

Despite the benefits and advancements in awning manufacturing, manufacturers face several challenges, including:

- Intense competition in the market

- Rising material and labor costs

- Meeting changing regulatory requirements and standards

The Future of Awning Manufacturing

The future of awning manufacturing looks promising, with continued innovation and advancements in technology, design, and sustainability.

Conclusion

Awning manufacturing is a dynamic industry that plays a vital role in enhancing the functionality and aesthetics of residential and commercial properties. By understanding the different types, materials, processes, and considerations involved, consumers can make informed decisions when choosing awnings for their spaces.

FAQs

How long does it take to manufacture an awning?

- The manufacturing timeline can vary depending on factors such as the complexity of the design, availability of materials, and the manufacturer’s workload. On average, it may take anywhere from a few days to a few weeks to complete the manufacturing process.

Can awnings be customized to fit specific dimensions?

- Yes, most awning manufacturers offer customization options to tailor the size, shape, and design of the awning to the client’s specifications.

What maintenance is required for awnings?

- Regular maintenance, such as cleaning the fabric and inspecting the hardware for any signs of wear or damage, is recommended to prolong the lifespan of awnings. Specific maintenance requirements may vary depending on the type of awning and its exposure to environmental elements.

Are awnings suitable for all weather conditions?

- While awnings provide protection from sun, rain, and mild wind, they may not be suitable for extreme weather conditions such as hurricanes or heavy snowfall. It’s essential to consider the climate and location when installing awnings and to take appropriate precautions to ensure their durability and safety.

Can awning fabric be replaced if damaged?

- Yes, in most cases, awning fabric can be replaced if it becomes damaged or worn out over time. Many manufacturers offer replacement fabric options, allowing customers to refresh the appearance of their awnings without replacing the entire structure.

GENERAL

The Versatility of Retractable Structures: Enhancing Spaces with Flexibility

Retractable structures have revolutionized the way we design and utilize spaces, offering flexibility, and functionality like never before. From retractable roofs to movable walls, these innovative architectural elements have become increasingly popular across various industries. In this article, we delve into the world of retractable structures, exploring their history, benefits, applications, and future trends.

History of Retractable Structures

Retractable structures have a rich history dating back centuries. One of the earliest examples dates back to ancient Roman times, where amphitheaters were equipped with retractable awnings to provide shade during events. Over the years, advancements in technology and engineering have led to the development of more sophisticated retractable systems.

Types of Retractable Structures

Retractable Roofs

Retractable roofs are perhaps the most common type of retractable structure, commonly found in sports stadiums and outdoor venues. These roofs can open and close, allowing for natural ventilation and exposure to the elements when desired.

Retractable Walls

Retractable walls offer the flexibility to transform indoor spaces seamlessly. Whether it’s dividing a large area into smaller sections or opening up a room to the outdoors, retractable walls provide versatility in design and functionality.

Retractable Floors

Retractable floors, although less common, are gaining popularity in residential and commercial settings. These floors can be raised or lowered to create multi-functional spaces, such as swimming pools that can be covered and converted into dance floors or event spaces.

Benefits of Retractable Structures

Flexibility and Versatility

One of the primary benefits of retractable structures is their ability to adapt to changing needs and environments. Whether it’s accommodating different weather conditions or transitioning between indoor and outdoor spaces, retractables structures offer unmatched flexibility.

Energy Efficiency

Retractable structures can enhance energy efficiency by maximizing natural light and ventilation. By opening up spaces to the outdoors, buildings can reduce reliance on artificial lighting and HVAC systems, leading to potential cost savings and environmental benefits.

Enhanced Aesthetics

In addition to their functional benefits, retractable structures can enhance the aesthetics of a space. Whether it’s showcasing architectural design or creating a unique ambiance, retractable elements add visual interest and sophistication to any environment.

Applications of Retractable Structures

Sports Venues

Retractable roofs have become a staple feature in modern sports stadiums, allowing events to take place rain or shine. These roofs provide spectators with a comfortable viewing experience while maintaining the integrity of the game.

Residential Spaces

In residential settings, retractable structures offer homeowners the opportunity to maximize outdoor living spaces. Whether it’s creating a seamless transition between indoor and outdoor areas or providing shade and protection from the elements, retractables structures add value and functionality to homes.

Commercial Buildings

From restaurants and cafes to retail stores and event venues, retractables structures are transforming the way commercial spaces are designed and utilized. These structures enable businesses to create dynamic and inviting environments that cater to diverse needs and preferences.

Considerations When Implementing Retractable Structures

While retractable structures offer numerous benefits, there are several factors to consider when implementing them:

Cost

The cost of installing and maintaining retractables structures can vary depending on factors such as size, materials, and complexity. It’s essential to weigh the upfront investment against the long-term benefits and consider the potential return on investment.

Maintenance

Retractables structures require regular maintenance to ensure optimal performance and longevity. This may include inspections, lubrication, and repairs as needed. Proper maintenance can help prevent costly issues and prolong the life of the structure.

Durability

Durability is another crucial factor to consider when choosing retractables structures. High-quality materials and construction methods are essential to withstand exposure to the elements and frequent operation. Investing in durable materials and professional installation can help ensure the longevity and reliability of the structure.

Future Trends in Retractable Structures

As technology continues to advance, we can expect to see exciting innovations in retractable structures. From enhanced automation and remote control capabilities to sustainable materials and energy-efficient design, the future of retractables structures is bright and promising.

Conclusion

Retractable structures have transformed the way we design and experience spaces, offering unparalleled flexibility, functionality, and aesthetic appeal. Whether it’s creating dynamic sports venues, versatile residential spaces, or innovative commercial buildings, retractables structures continue to push the boundaries of architectural design and engineering.

FAQs

1. Are retractable structures suitable for all climates?

Retractables structures can be designed to withstand various weather conditions, making them suitable for a wide range of climates. However, factors such as wind, snow, and extreme temperatures may affect their performance and durability.

2. Can retractables structures be retrofitted into existing buildings?

Yes, retractables structures can often be retrofitted into existing buildings with careful planning and design. However, the feasibility of retrofitting will depend on factors such as structural integrity, space availability, and budget constraints.

3. How long do retractables structures typically last?

The lifespan of retractables structures can vary depending on factors such as materials, usage, and maintenance. With proper care and maintenance, high-quality retractables structures can last for decades.

4. Are retractables structures energy-efficient?

Retractables structures can enhance energy efficiency by maximizing natural light and ventilation. By reducing reliance on artificial lighting and HVAC systems, retractables structures can help lower energy consumption and operating costs.

5. Can retractable structures be customized to fit specific design requirements?

Yes, retractables structures can be customized to fit specific design requirements, including size, shape, and functionality. Whether it’s creating a unique architectural feature or maximizing space utilization, retractables structures offer endless possibilities for customization.

TECHNOLOGY4 months ago

TECHNOLOGY4 months agoBlog Arcy Art: Where Architecture Meets Art

ENTERTAINMENT1 week ago

ENTERTAINMENT1 week agoExploring the Kristen Archives: A Treasure Trove of Erotica and More

ENTERTAINMENT4 days ago

ENTERTAINMENT4 days agoKiss KH: The Streaming Platform Redefining Digital Engagement and Cultural Currents

LIFESTYLE4 months ago

LIFESTYLE4 months agoThe Disciplinary Wives Club: Spanking for Love, Not Punishment

LIFESTYLE1 week ago

LIFESTYLE1 week agoWho Is Sandra Orlow?

GENERAL4 months ago

GENERAL4 months agoWhat are stories of male chastity? A Comprehensive Guide

EDUCATION4 days ago

EDUCATION4 days agoLingrohub Platform: A Complete Student Access Guide

ENTERTAINMENT4 weeks ago

ENTERTAINMENT4 weeks agoMonkeyGG2: Your Personal Gaming Hub